ANTIQUE MICROSCOPES AND OTHER ANTIQUE SCIENTIFIC INSTRUMENTS

MICROSCOPE-ANTIQUES.COM © 2013-2020

COMPRESSORS OR COMPRESSORIA

| INTRODUCTION | A PARTIAL LIST OF COMPRESSORS |

INTRODUCTION:

As interest in studying living (and moving) organisms grew, various methods were devised to allow this to be accomplished under the microscope. In its most basic form, a moving organism was followed using a moveable stage, or better, a moving set of optics such as was devised for the 'Trembley-Ellis Aquatic' type of microscope. Another method is to use a 'live box' also known as a 'live cage' or 'Animalcule Cage.' This device was designed to observe living specimens such as protozoa in a liquid medium. It could also simply trap an insect in an enclosed space. In some cases, some degree of pressure could be applied to the top cap of these live-boxes to try to immobilize moving specimens, but the adjustment of these devices is imprecise and it was hard to get just the right pressure for certain purposes. Hence the Compressor or Compressorium was devised and this page is about them. In the near future, a page devoted to live boxes will also be found on this site. Varley's version of the livebox, which he described as his 'Capillary Tablets or Cages' in the Journal of the Society of Arts, Volume 48, Part II, pages 343 to 344 in 1831, could be used as a compressor because its top screwed down. This was also problematic, for although the pressure could be slowly adjusted, the rotation while screwing down could distort the specimen.

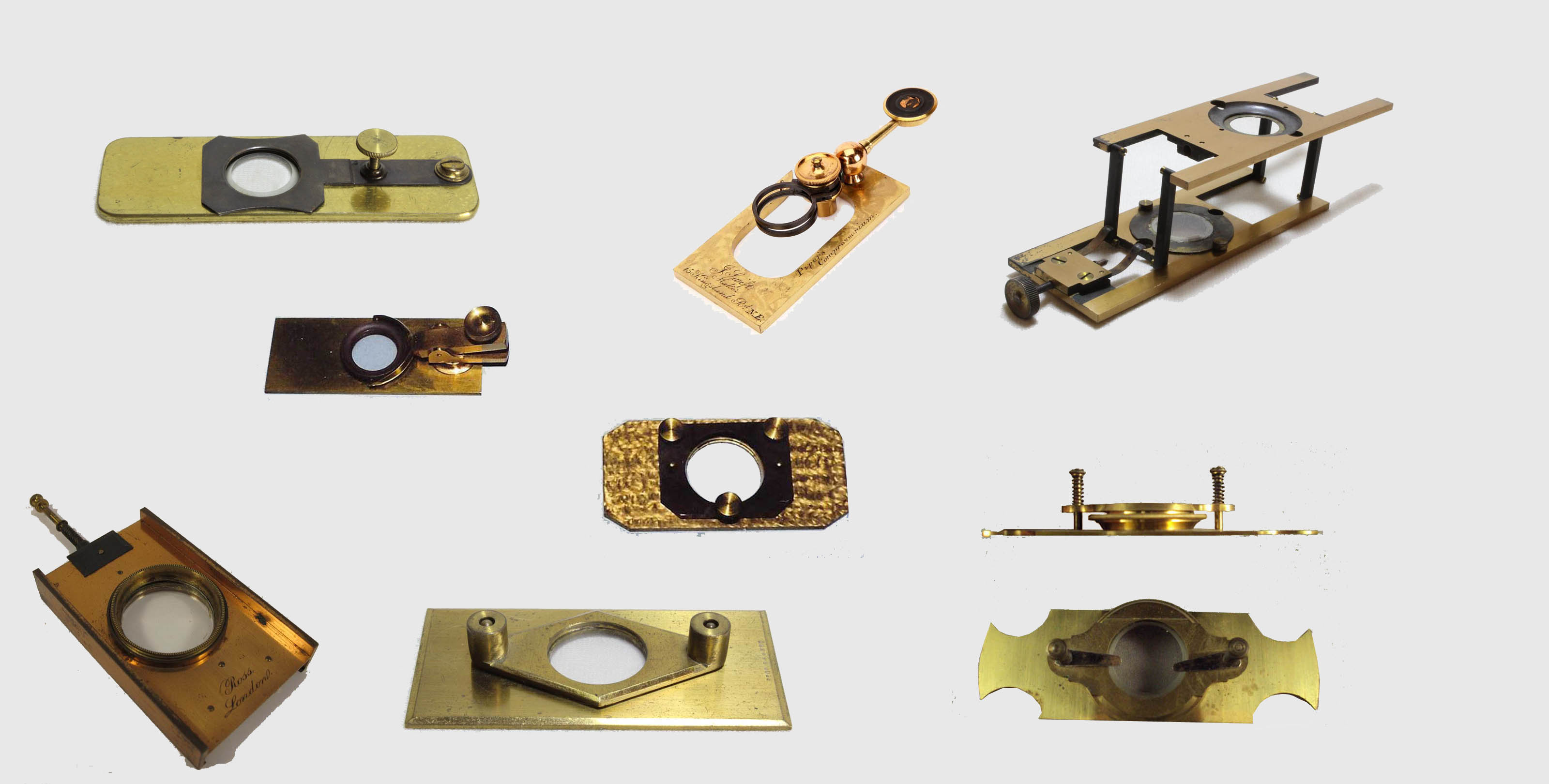

The famous histologist Purkinje is often credited with inventing the first dedicated compressor about or before 1834, though he used it to flatten histology sections rather than immobilize moving organisms. The Purkinje compressor was described and pictured, (in German), in Muller's 'Archiv fur ANATOMIE, PHYSIOLOGIE UND WISSENSCHFTLICHE MEDICIN... The compressorium or compressor, is therefore, an instrument which evolved from the live box, but allows both a finer adjustment of the pressure applied and also, if needed, a higher or lesser and subtle degree of pressure. It therefore can also be used, unlike the live box, to crush specimens and make them thinner and more transparent allowing transillumination or it can also be used for very delicate work, as in immobilizing motile protozoa. Many variations of this device were produced over the years, and the most recent version, the Taylor compressor, is a late 20th century improvement on Rousselet's invention. Some variations allow a relatively limited amount of pressure (i.e. the gravity compressors), while others, like the Lever compressor allow a considerable amount. The large glass plate compressors used to flatten teased pieces of meat during inspection for trichinella larvae can apply even more pressure. Between these extremes are the Lister compressor (by James Smith and successors) and the Beck parallel plate compressor. Most of these instruments allow one position of use, but the Parallel plate devices can be reversed, as can Ross' Reversible Compressorium; Piper's compressor allows full rotation of the (relatively small) compressor permitting even more angles of observation. It also had the advantage that it could be reversed so the subject could be viewed from the opposite side without removing it from the stage. Its disadvantage was the distance from the condenser making it unsuitable for use with high powers. Of note, many years later Watson made a similar version and in the 1891 edition of Carpenter's The Microscope and its Revelations a similar device was reportedly designed by W. Rowland as pictured on page 296 of that book.

The famous histologist Purkinje is often credited with inventing the first dedicated compressor about or before 1834, though he used it to flatten histology sections rather than immobilize moving organisms. The Purkinje compressor was described and pictured, (in German), in Muller's 'Archiv fur ANATOMIE, PHYSIOLOGIE UND WISSENSCHFTLICHE MEDICIN... The compressorium or compressor, is therefore, an instrument which evolved from the live box, but allows both a finer adjustment of the pressure applied and also, if needed, a higher or lesser and subtle degree of pressure. It therefore can also be used, unlike the live box, to crush specimens and make them thinner and more transparent allowing transillumination or it can also be used for very delicate work, as in immobilizing motile protozoa. Many variations of this device were produced over the years, and the most recent version, the Taylor compressor, is a late 20th century improvement on Rousselet's invention. Some variations allow a relatively limited amount of pressure (i.e. the gravity compressors), while others, like the Lever compressor allow a considerable amount. The large glass plate compressors used to flatten teased pieces of meat during inspection for trichinella larvae can apply even more pressure. Between these extremes are the Lister compressor (by James Smith and successors) and the Beck parallel plate compressor. Most of these instruments allow one position of use, but the Parallel plate devices can be reversed, as can Ross' Reversible Compressorium; Piper's compressor allows full rotation of the (relatively small) compressor permitting even more angles of observation. It also had the advantage that it could be reversed so the subject could be viewed from the opposite side without removing it from the stage. Its disadvantage was the distance from the condenser making it unsuitable for use with high powers. Of note, many years later Watson made a similar version and in the 1891 edition of Carpenter's The Microscope and its Revelations a similar device was reportedly designed by W. Rowland as pictured on page 296 of that book.

Although Varley's original live box, can also serve as a compressor, and has a screw-on top, allowing fine adjustments, this method was abandoned, as the twisting motion so applied often distorted the specimen. For this reason, later versions of his design have a press-fitting cap and were less used to apply pressure to the specimen but to simply observe a thin layer of a liquid medium.

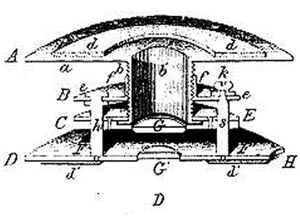

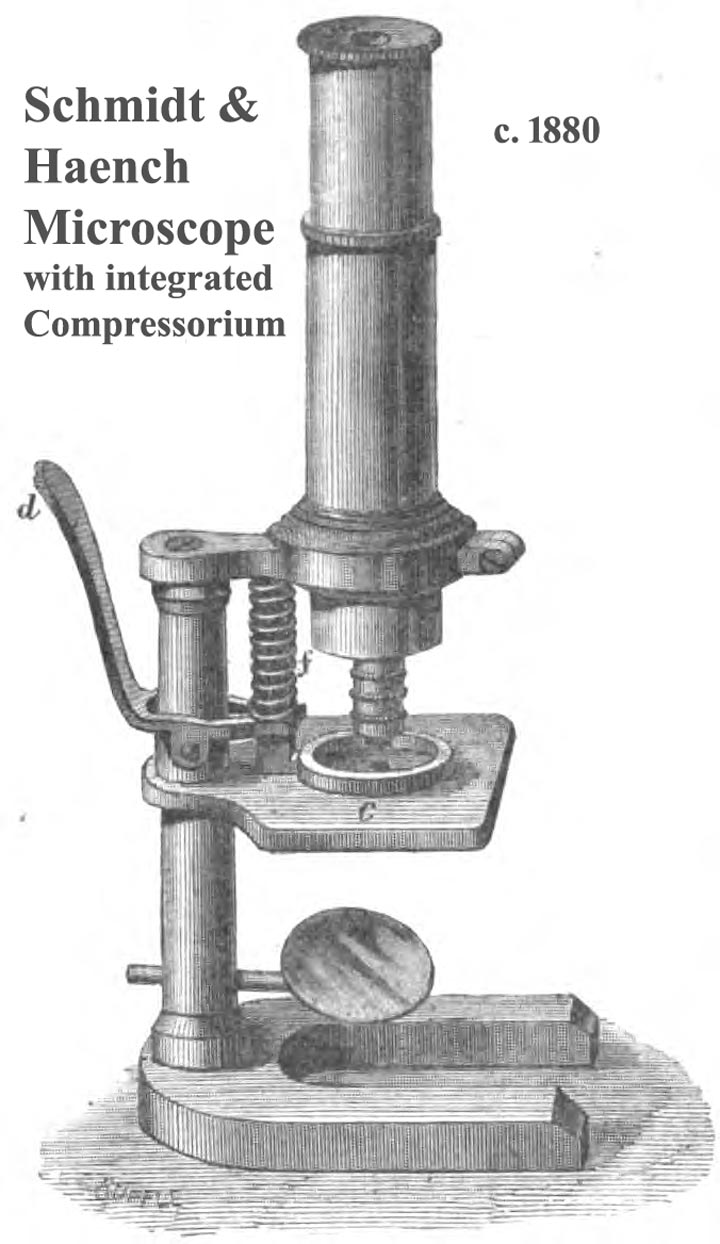

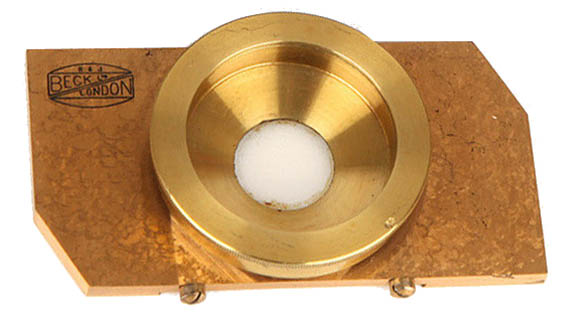

In the late 19th century, dedicated Trichinoscopes were sold in large numbers for meat inspection. Although these were usually just low power microscopes with a larger stage and a large glass compressorium, some examples with integrated compressors were made such as that by Schmidt & Haench. Although in the past a heavy glass compressor was used to flatten teased out fibers of meat to make them translucent, in order to inspect the meat for trichinella larvae, the process of meat inspection by this method was made a bit easier by partial digestion of the meat with enzymes. More recent methods use a more complete digestion of the muscle and the parasites are found in the sediment, and are examined with a stereomicroscope without the need for a compressor.

In the late 19th century, dedicated Trichinoscopes were sold in large numbers for meat inspection. Although these were usually just low power microscopes with a larger stage and a large glass compressorium, some examples with integrated compressors were made such as that by Schmidt & Haench. Although in the past a heavy glass compressor was used to flatten teased out fibers of meat to make them translucent, in order to inspect the meat for trichinella larvae, the process of meat inspection by this method was made a bit easier by partial digestion of the meat with enzymes. More recent methods use a more complete digestion of the muscle and the parasites are found in the sediment, and are examined with a stereomicroscope without the need for a compressor.

NOTE: All of the compressors shown on this page are in the author's collection except for the Varley, Bulloch, Simpler Ross Reversible, and Piper examples from other private collections. I am grateful to the owners of these for allowing me to share them with you. Please note that I have not attempted to show every compressor ever invented, as there are simply too many of them, and I do not (and could never) have examples of all of them, but I do think this is a good representative sample of the most common types.

PARTIAL LIST OF COMPRESSORIA

PLEASE CLICK ON THE IMAGES FOR MORE INFORMATION, WHERE AVAILABLE

COMPRESSORS:

THE VARLEY 'CAPILLARY TABLET'

Although usually considered a livebox, Varley's 'Capillary Tablet,' with its screw-on top, could be used to apply compression to the specimen. For this reason, it might be considered an early form of compressor as well as a live box.

Although usually considered a livebox, Varley's 'Capillary Tablet,' with its screw-on top, could be used to apply compression to the specimen. For this reason, it might be considered an early form of compressor as well as a live box.

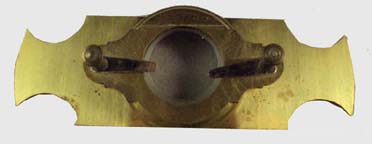

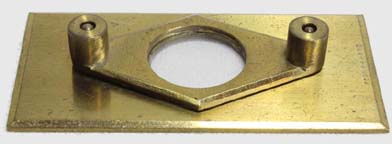

BROOKE TYPE:

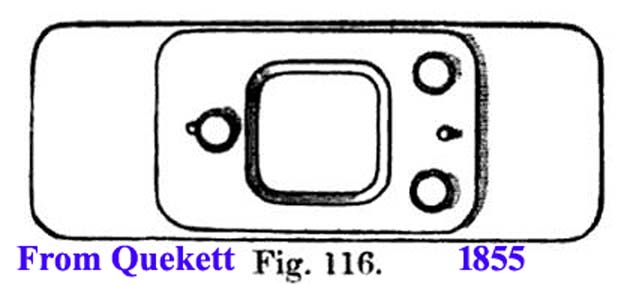

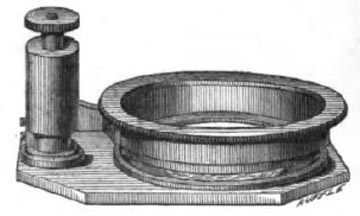

This type of compressor is one of a class known as 'gravity compressors.' This means that the pressure applied to the specimen is limited to what the weight of the top pressure plate applies without any leverage or springs to apply a greater amount of force. The bottom plate of brass has a central hole. Over this hole is the bottom support for the specimen made of glass. The top plate, with thin glass on its bottom surface, rides freely on two vertical pins. The distance of the bottom of this top plate is regulated by three thumbscrews which project from its bottom and act like little 'legs.' As each screw is loosened, the weight of the top plate brings the glass on its bottom closer to the glass on the bottom plate. The maximum pressure applied, is simply a function of the weight of the top brass plate. This device has advantages of easy access, low cost, and easy cleaning. Disadvantages include the need to adjust three different thumbscrews to apply equal pressure all around the object being studied, and the fact that more severe pressure, beyond the weight of the top plate, cannot be applied.

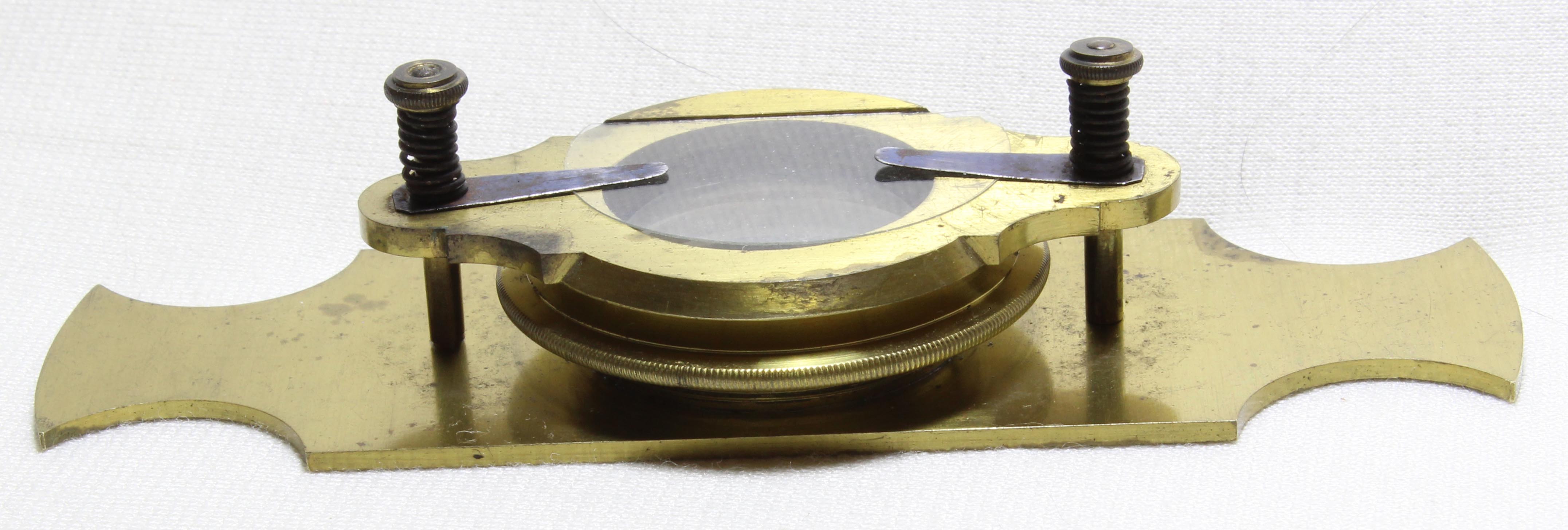

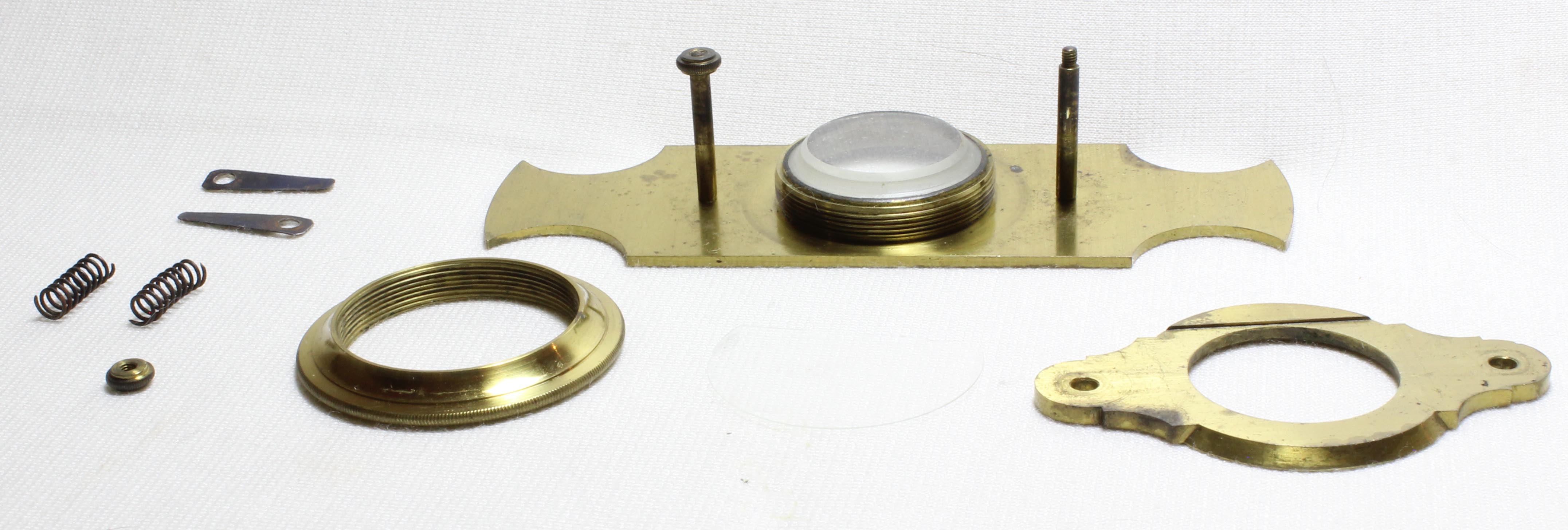

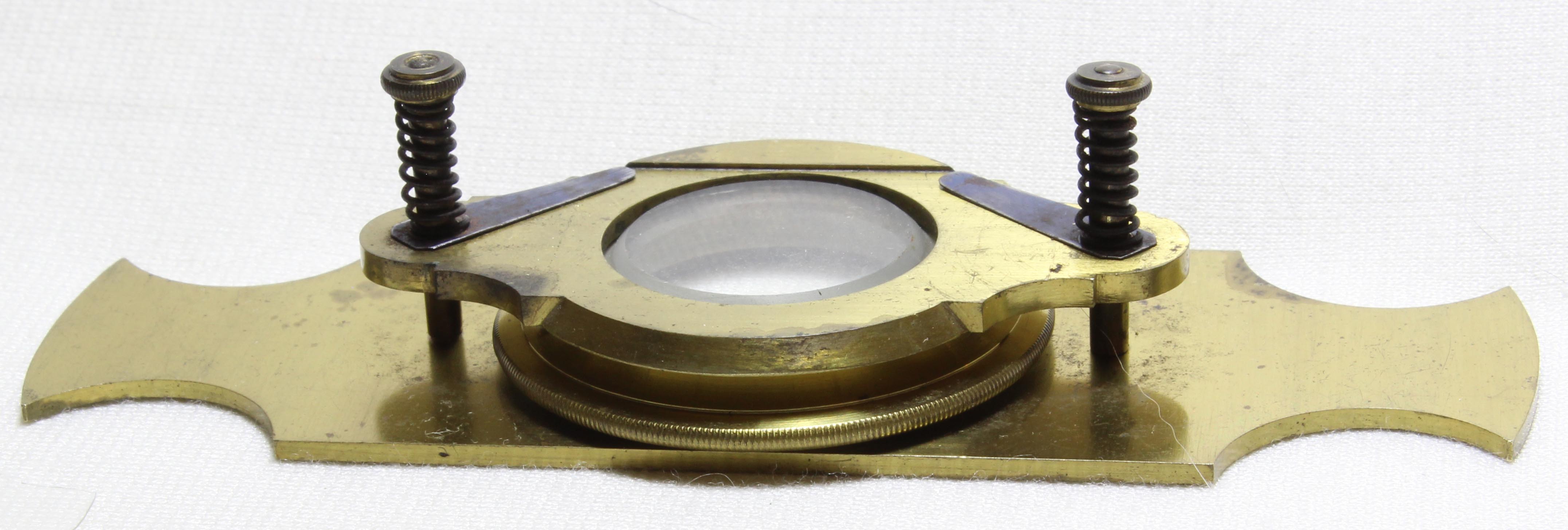

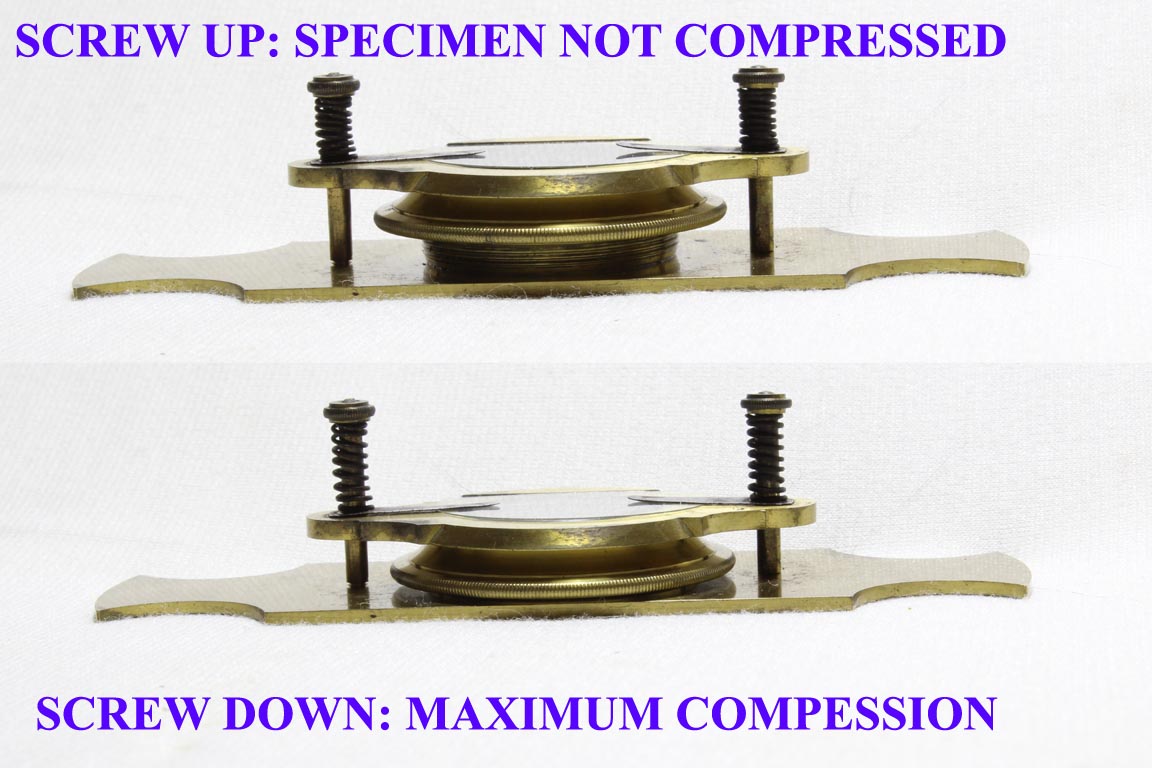

LISTER TYPE:

The Lister compressor, also referred to (by Beck) as a 'screw live box,' was first manufactured by James Smith. It is a compressor with springs to apply greater pressure than that of the gravity compressors. It consists of a bottom brass plate, with a cylinder permanently erected upon it; at the top of this cylinder is permanently mounted the bottom glass surface, just like a live-box. The difference though is that the outside of this cylinder is threaded and a large knurled ring rides in these threads. The top plate of the compressor rides on two upright posts, with springs applying downward pressure against the knurled ring on the bottom plate cylinder. If the knurled ring is screwed all the way down, the glass in the top plate is pressed against the glass at the top of the cylinder with the full force of the springs. If the knurled ring is unscrewed, it pushes up on the top plate, lifting it off the bottom glass.

The glass on the bottom part has beveled edges. There are two steel tabs on top of the top plate to hold a cover slip in place. When the ring is unscrewed, it pushes up on the top plate, and when screwed down, it allows the top plate, pushed down by the springs, to compress the specimen upon the bottom glass support. In effect this allows a fine degree of adjustment to the degree of compression, which is more forceful than the gravity types due to the springs.

In use, the knurled ring is unscrewed all the way up with no cover slip on the top plate. The specimen is then placed on the glass at the top of the cylinder of the bottom plate; once the specimen is in place, a cover slip is placed under the two steel clips of the top plate, and the knurled ring is slowly screwed down until the desired degree of compression is achieved. The top plate has a straight edge against which a coverslip with one flat edge can register.

The Lister compressor was made and sold by James Smith no later than 1840, continued to be sold by his successors and was still offered in the 1891 catalog of James Swift & Son and the 1894 catalog of Smith's successors R. & J Beck. Ross also made a variation of the Lister compressorium, with four instead of two upright posts. The Lister compressor has an advantage over many others in that it is a very simple matter to change the top cover glass by simply moving the spring steel fingers away.

YEATES TYPE:

The Yeates compressor, first described in 1842 by George Yeates of Dublin, has a bayonett fitting on the bottom to fit in the center of a suitable stage. Such a stage would be part of some examples of Pritchard microscopes. It had a removable center holding the bottom plate of glass and a design that kept the two glass plates parallel. With the center supporting tube removed, the stage clips on top could support an ordinary slide. At the time this device was invented it was not appreciated that this distance from the stage opening was a disadvantage reducing the ability to use higher powers to greatest advantage.

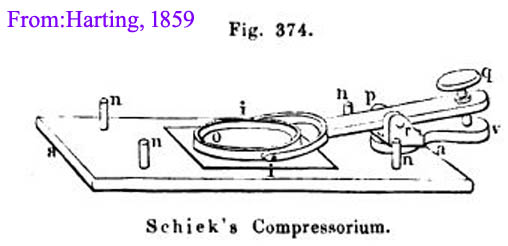

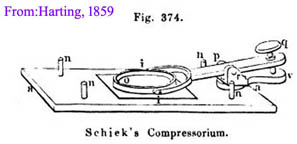

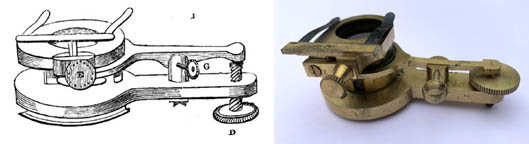

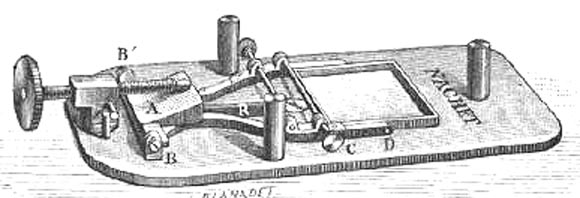

LEVER or SCHIECK TYPE:

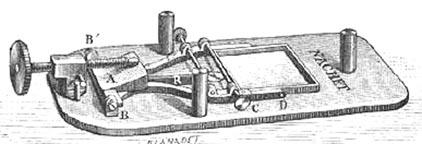

The lever or Schiek-type compressor, allows direct pressure to be applied to greater degree than the other compressors shown on this page. A spring, which pushes the covering glass end of the lever upward, keeps the compressor from applying pressure except as applied by the opposing thumbscrew. This type of compressor may have been invented by Schieck and was shown in German texts as early as 1836 where it is often referred to as a Schieck Compressorium. In Schieck's German compressorium(upper left), a notable difference from the British versions(right) was the presence of four upright pins which would allow it to be reversed on the stage, though of course now much higher off the stage. A Nachet variant, shown below the picture of Schiek's original from Harting, has only three legs. The British version, shown to the right, had no pins for using it as a reversible compressor, the English having invented other types of reversible compressors.

Changing the cover glass on these compressors requires removing the old one and gluing on a new one. One way of making this easier was to use a glue consisting of a mixture of, e.g., Canada Balsam and Beeswax. The author is grateful to Dr Brian Stevenson for supplying the images of the Nachet Scheik Compressor.

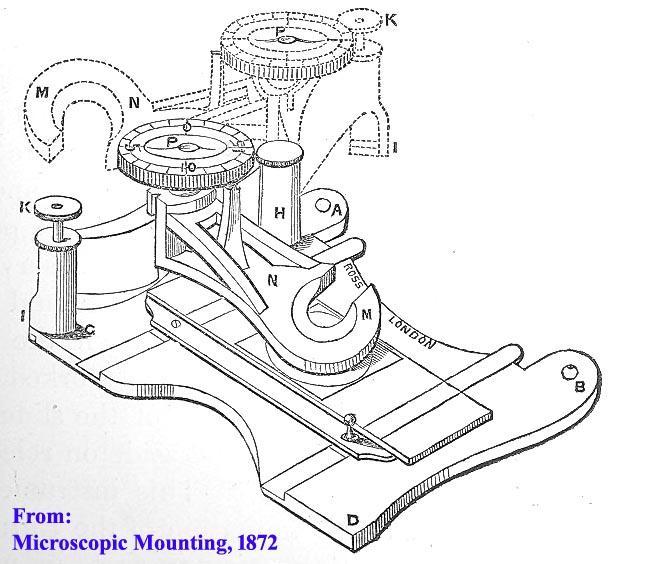

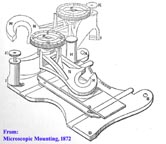

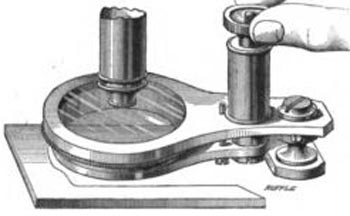

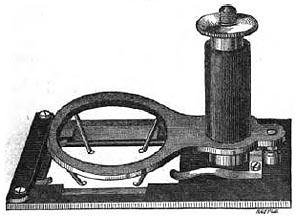

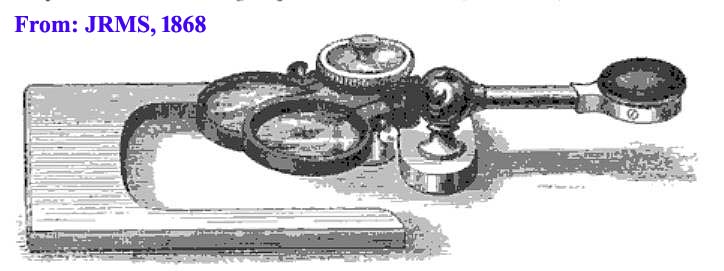

ROSS SWING-OUT COMPRESSORIUM STAGE (1862-72):

This compressor was apparently first exhibited by Thomas Ross in the Great Exhibition in London in 1862. It was designed to sit firmly on top of the existing stage with pins holding it in place. The compressorium could be completely swung out of the way, leaving the stage with a typical slide rest. In operation, a normal slide and cover slip would be used, and the compressing plate, N-M would be lowered on top of the cover slip with pressure regulated by the knurled knob P. (Thanks to Jim Solliday for information and images of this compressor).

This compressor was apparently first exhibited by Thomas Ross in the Great Exhibition in London in 1862. It was designed to sit firmly on top of the existing stage with pins holding it in place. The compressorium could be completely swung out of the way, leaving the stage with a typical slide rest. In operation, a normal slide and cover slip would be used, and the compressing plate, N-M would be lowered on top of the cover slip with pressure regulated by the knurled knob P. (Thanks to Jim Solliday for information and images of this compressor).

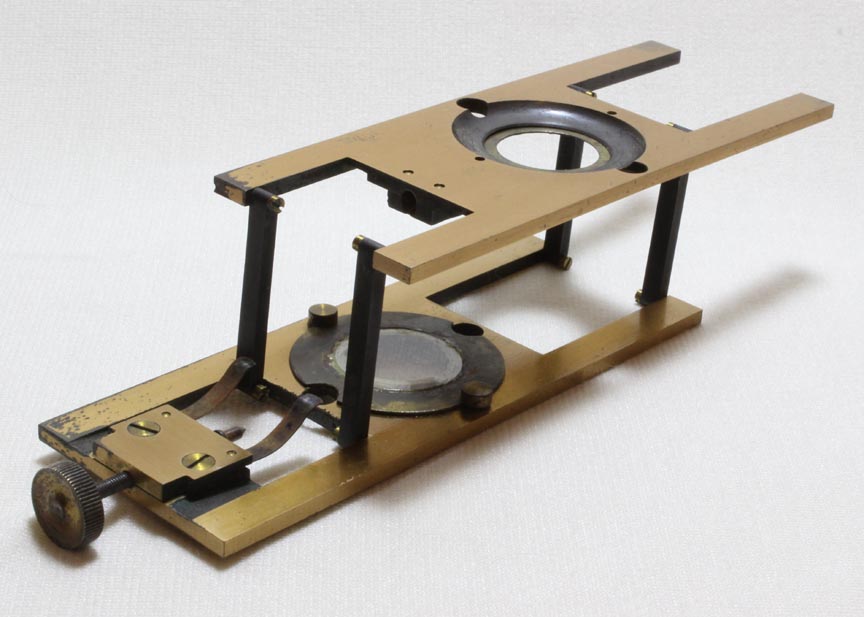

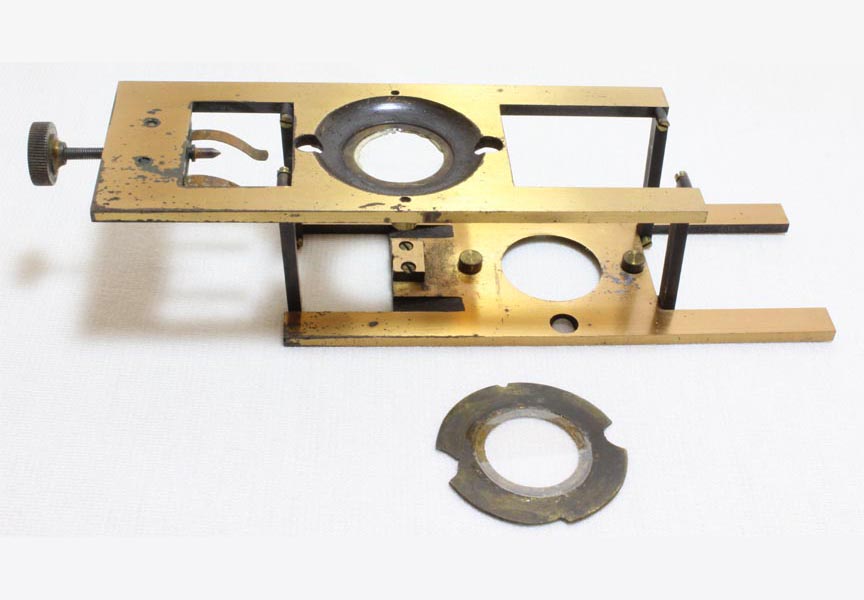

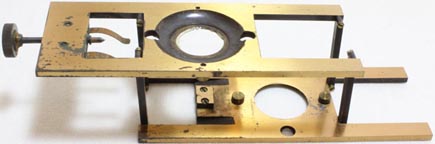

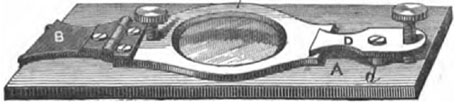

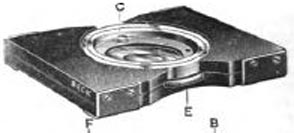

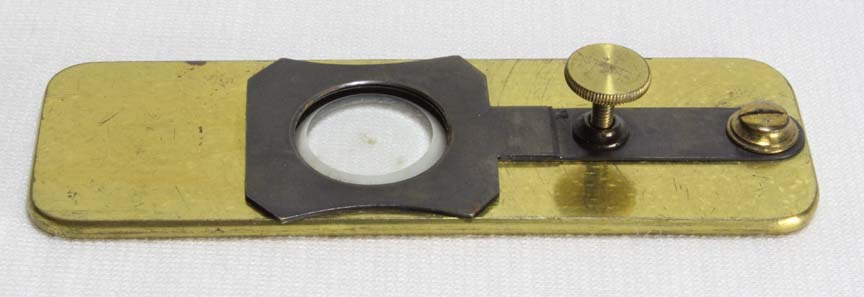

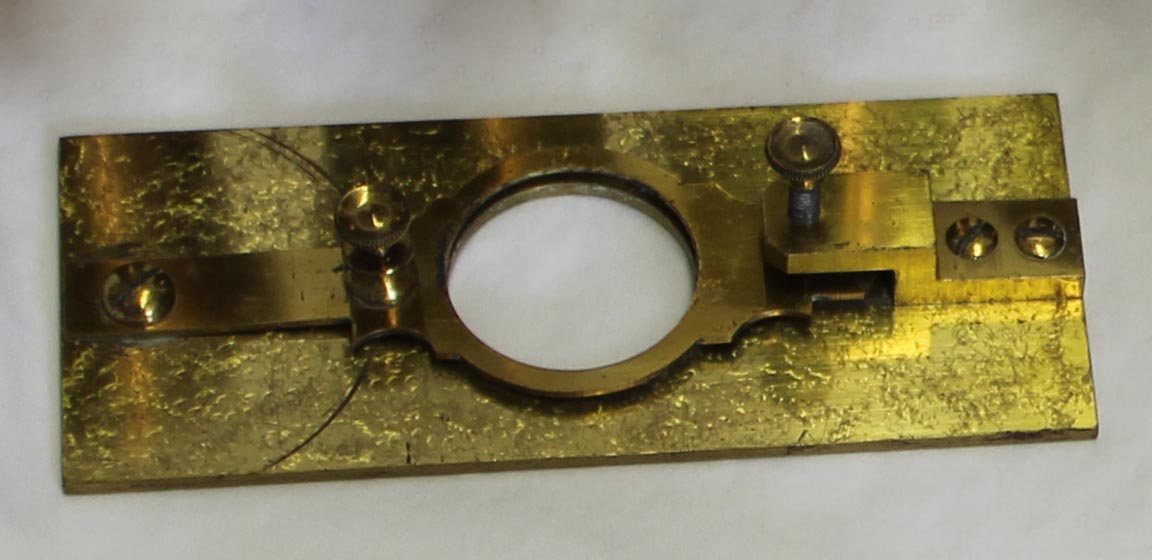

PARALLEL PLATE TYPE (BECK):

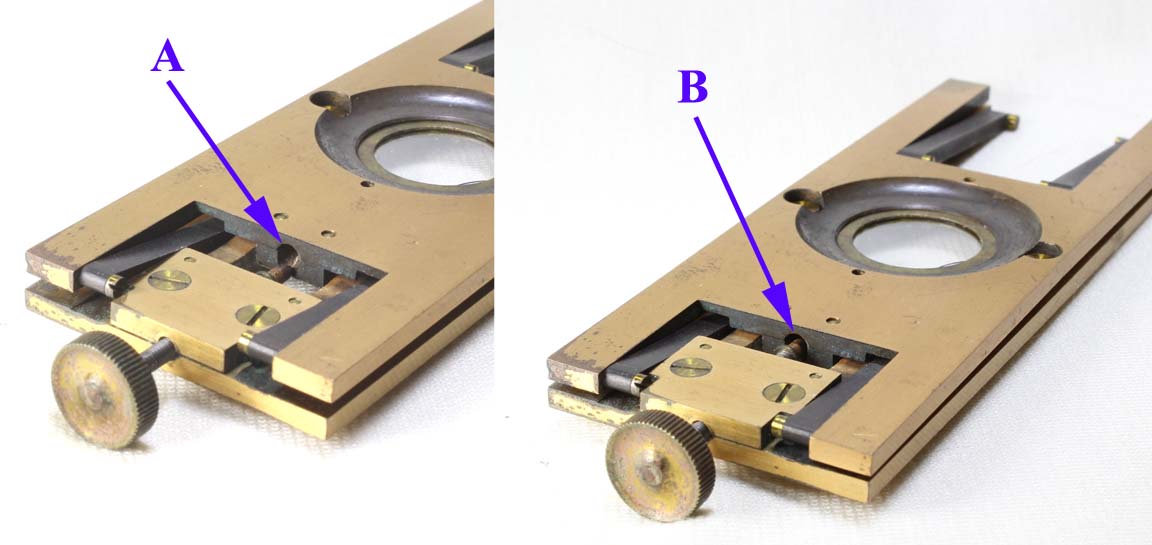

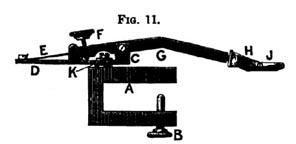

The Beck Parallel Plate compressor is constructed in such a way that it resembles a parallelogram. Its chief advantages are its thin profile and reversibility. The illustration above to the right shows one of the glass supports removed. There is one for the top plate and one for the bottom. Cover glasses are glued to these metal disks which lock into place and it makes it a much simpler matter to clean them or replace them. Again, a glue that contains some beeswax would make removal easier. Most surviving examples of the Beck Parallel plate compressor are missing these round metal fittings to hold the cover glasses. Early versions did not use these fittings, but simply used small knobs to fasten large rectangular coverslips to the plates and an example of this type is on the site on another page. To use this device, the two plates are pushed together after the specimen is placed on the bottom glass. The springs push the two plates apart thus maintaining tension. When the two plates are relatively close to one another, as the horizontal screw fixed to the lower plate is advanced (A-->B), its tip engages with an angled channel(*) in the black metal attached to the top plate, drawing the top plate downward. Although it appears this device would maintain parallelism, as illustrated by the image below, this is not necessarily the case. In addition, as it is tightened further, it can bend.

The Beck Parallel Plate compressor is constructed in such a way that it resembles a parallelogram. Its chief advantages are its thin profile and reversibility. The illustration above to the right shows one of the glass supports removed. There is one for the top plate and one for the bottom. Cover glasses are glued to these metal disks which lock into place and it makes it a much simpler matter to clean them or replace them. Again, a glue that contains some beeswax would make removal easier. Most surviving examples of the Beck Parallel plate compressor are missing these round metal fittings to hold the cover glasses. Early versions did not use these fittings, but simply used small knobs to fasten large rectangular coverslips to the plates and an example of this type is on the site on another page. To use this device, the two plates are pushed together after the specimen is placed on the bottom glass. The springs push the two plates apart thus maintaining tension. When the two plates are relatively close to one another, as the horizontal screw fixed to the lower plate is advanced (A-->B), its tip engages with an angled channel(*) in the black metal attached to the top plate, drawing the top plate downward. Although it appears this device would maintain parallelism, as illustrated by the image below, this is not necessarily the case. In addition, as it is tightened further, it can bend.

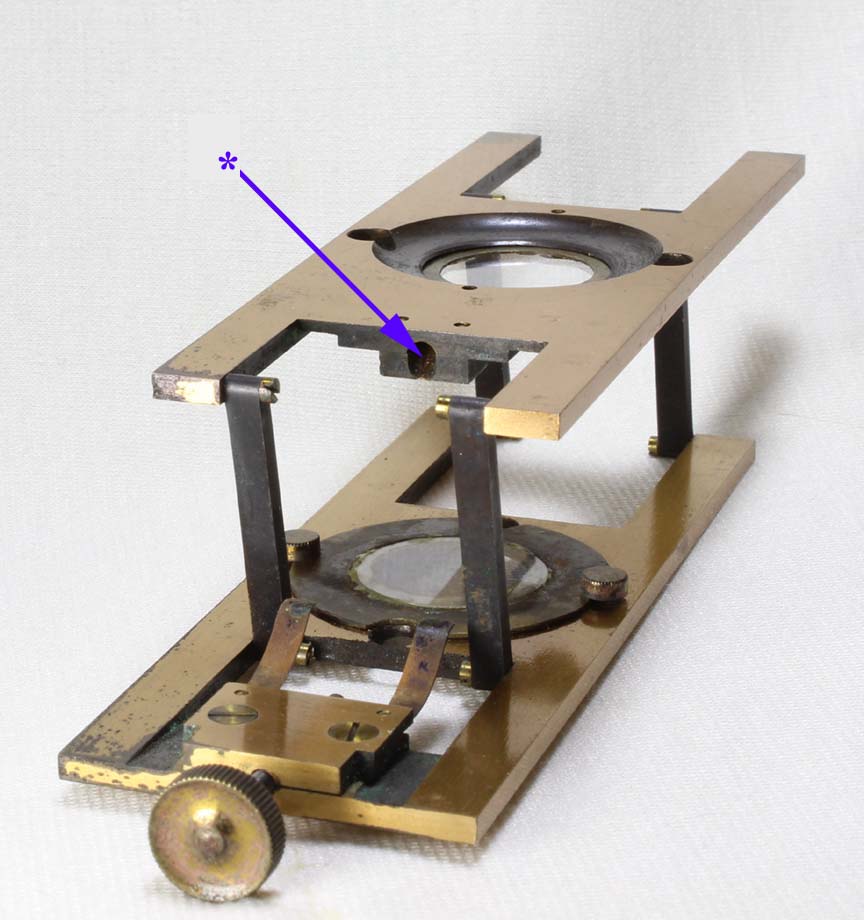

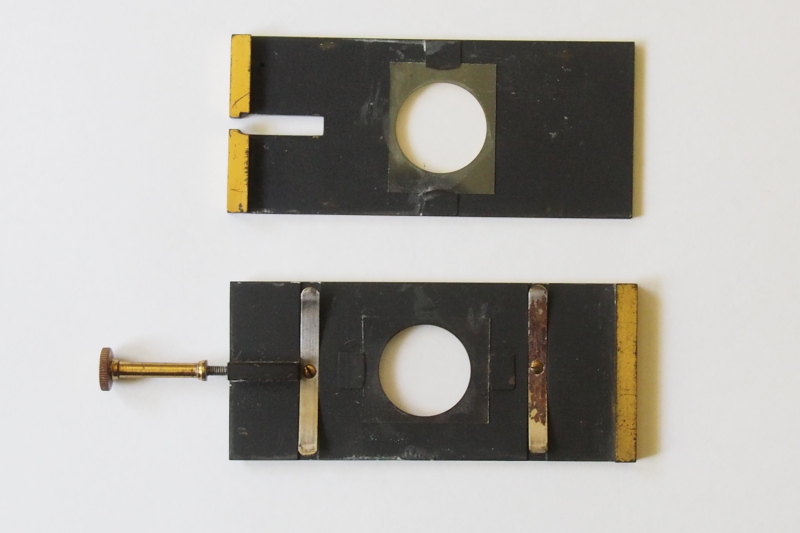

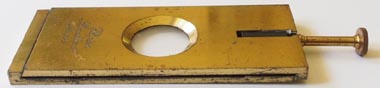

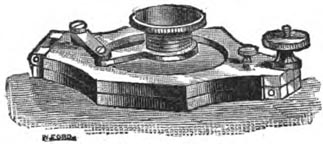

ROSS' REVERSIBLE TYPE (?1869-?):

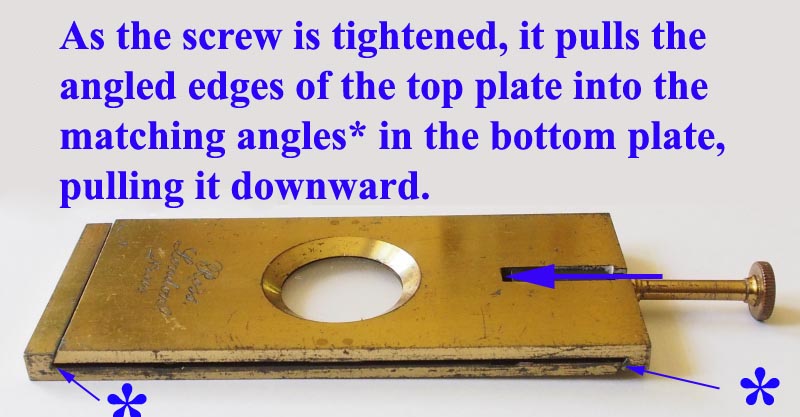

Ross made two versions of a reversible compressor. This is the thinner and simpler of the two. In his 1869 and 1872 catalogs, Ross offered a 'Ross Reversible Compressorium' By 1875, the 'Ross Improved Reversible Compressorium'(IRC) was listed. Strangely, the IRC was pictured in the 1875 catalog, but the illustration in the 1883 catalog seems to be the this less sophisticated model, with the caption still referring to the IRC. This model is harder to use than the next entry. In use, according to Dr. de Groot, the user needs to apply some manual pressure to the top plate while tightening the knob in order for it to properly compress the subject. The top plate rides in the angled grooves(*) on the right and left side of the bottom plate, and as the screw is tightened the top plate is pulled downward as it pushes further into the matching grooves. There are convenient tabs to hold cover glasses on each inside surface of the compressor. (Collection of Dr. Jurriaan de Groot).

Ross made two versions of a reversible compressor. This is the thinner and simpler of the two. In his 1869 and 1872 catalogs, Ross offered a 'Ross Reversible Compressorium' By 1875, the 'Ross Improved Reversible Compressorium'(IRC) was listed. Strangely, the IRC was pictured in the 1875 catalog, but the illustration in the 1883 catalog seems to be the this less sophisticated model, with the caption still referring to the IRC. This model is harder to use than the next entry. In use, according to Dr. de Groot, the user needs to apply some manual pressure to the top plate while tightening the knob in order for it to properly compress the subject. The top plate rides in the angled grooves(*) on the right and left side of the bottom plate, and as the screw is tightened the top plate is pulled downward as it pushes further into the matching grooves. There are convenient tabs to hold cover glasses on each inside surface of the compressor. (Collection of Dr. Jurriaan de Groot).

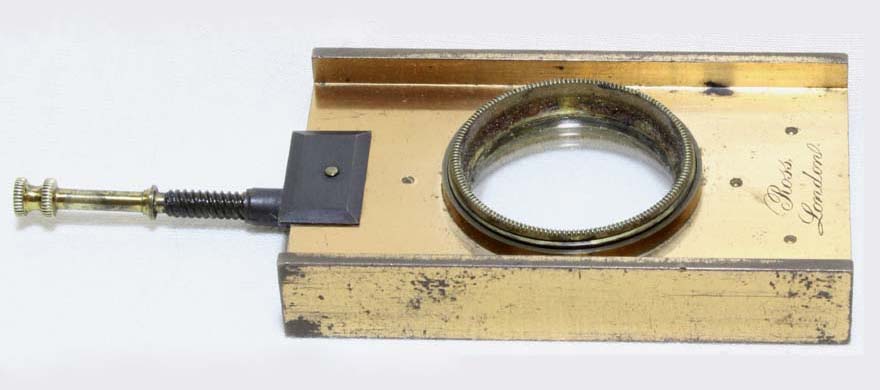

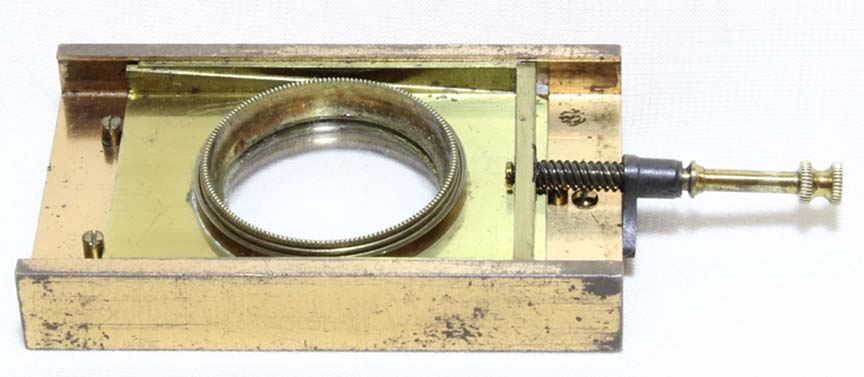

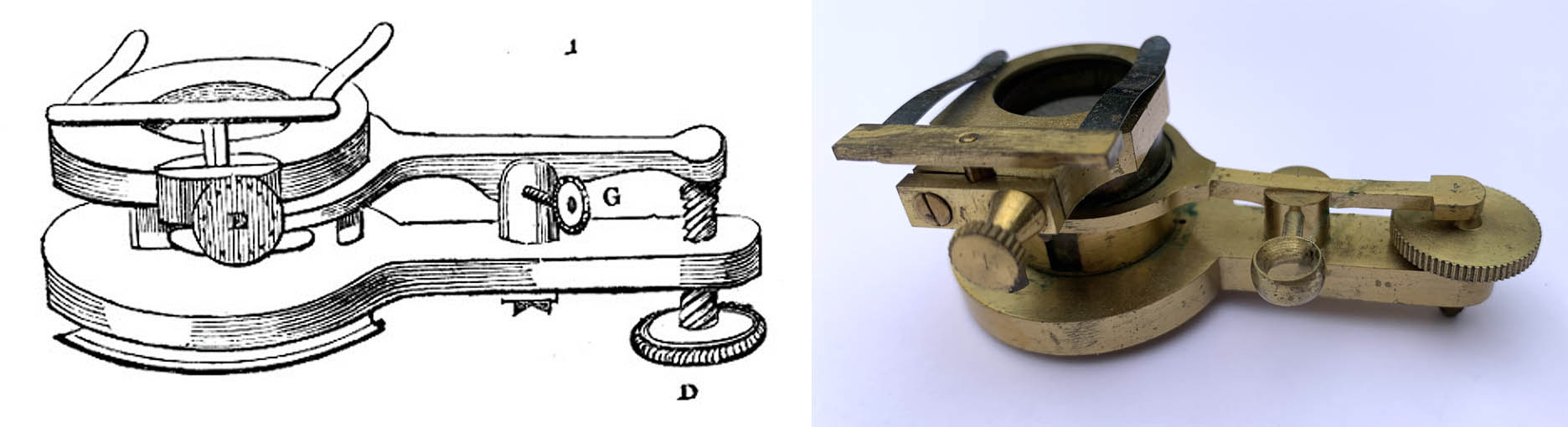

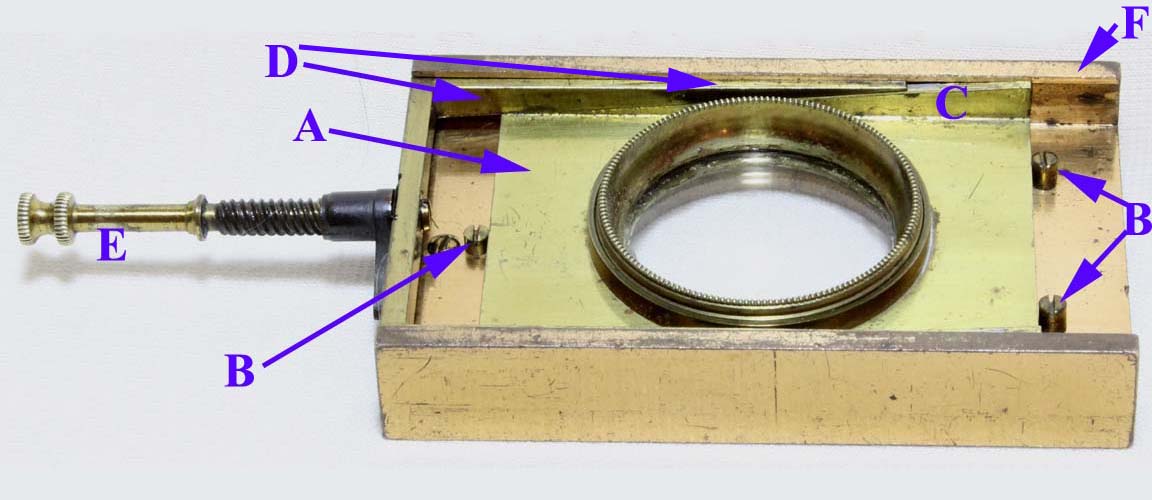

ROSS' IMPROVED REVERSIBLE TYPE (1869-):

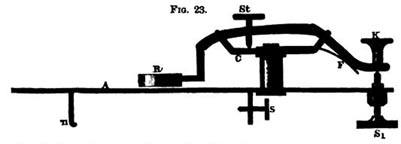

The 'Improved Ross Reversible compressor,' first reported in the Monthly Microscopical Journal of 1869, was apparently offered in Ross catalogs from 1869 through at least 1883. The main part of the instrument consists of an 'I-beam'-shaped base plate with a threaded hole into which screws a knurled ring onto which a glass base plate is glued. On the opposite side, as shown to the right, a secondary plate, A, also with a knurled theaded ring carrying a thin glass plate, floats between three keeper posts, B. This secondary plate is pushed away from the main plate by two springs pushing up from the bottom plate(not shown, but virtually identical to the those in the preceding Ross entry). The secondary plate has wedge-shaped top edges, C. The two-pronged fork, with a wedge-shaped tine on each side, D, sits on top of the floating secondary plate. As the worm screw, E, is turned, it advances the fork which pushes down on the secondary plate. The tines of the fork are kept in contact with the bottom plate by a ledge, F, on either side of the compressor. This compressor was apparently Ross' answer to the Beck Parallel Plate compressor as the catalogs referred to it 'for securing parallelism of the surfaces.' To this author, this type is more likely to achieve that goal than the Beck, which could bend as tightened and did not remain parallel despite its parallelogram design. This model of the Ross Reversible Compressor seems to work much better than the other Ross Reversible Compressor. Again like several other examples, the cover glasses must be glued into the knurled rings; beeswax in the glue would make them easier to remove or replace when needed.

The 'Improved Ross Reversible compressor,' first reported in the Monthly Microscopical Journal of 1869, was apparently offered in Ross catalogs from 1869 through at least 1883. The main part of the instrument consists of an 'I-beam'-shaped base plate with a threaded hole into which screws a knurled ring onto which a glass base plate is glued. On the opposite side, as shown to the right, a secondary plate, A, also with a knurled theaded ring carrying a thin glass plate, floats between three keeper posts, B. This secondary plate is pushed away from the main plate by two springs pushing up from the bottom plate(not shown, but virtually identical to the those in the preceding Ross entry). The secondary plate has wedge-shaped top edges, C. The two-pronged fork, with a wedge-shaped tine on each side, D, sits on top of the floating secondary plate. As the worm screw, E, is turned, it advances the fork which pushes down on the secondary plate. The tines of the fork are kept in contact with the bottom plate by a ledge, F, on either side of the compressor. This compressor was apparently Ross' answer to the Beck Parallel Plate compressor as the catalogs referred to it 'for securing parallelism of the surfaces.' To this author, this type is more likely to achieve that goal than the Beck, which could bend as tightened and did not remain parallel despite its parallelogram design. This model of the Ross Reversible Compressor seems to work much better than the other Ross Reversible Compressor. Again like several other examples, the cover glasses must be glued into the knurled rings; beeswax in the glue would make them easier to remove or replace when needed.

The Piper compressorium was reported in the

The Piper compressorium was reported in the

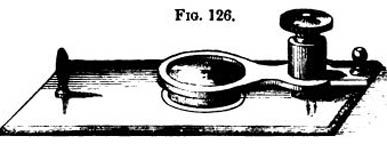

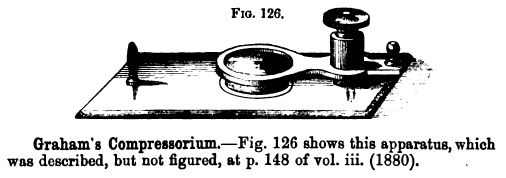

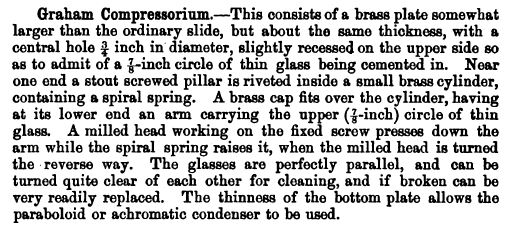

The Wenham type, with its thinner profile, was said to be especially suitable for use with dark ground illumination, as when using a Paraboloid condenser. The top plate is threaded to accept the knob. The top plate is springy and when the knob is turned counterclockwise, the top plate is lowered on the object being studied.

The Wenham type, with its thinner profile, was said to be especially suitable for use with dark ground illumination, as when using a Paraboloid condenser. The top plate is threaded to accept the knob. The top plate is springy and when the knob is turned counterclockwise, the top plate is lowered on the object being studied.

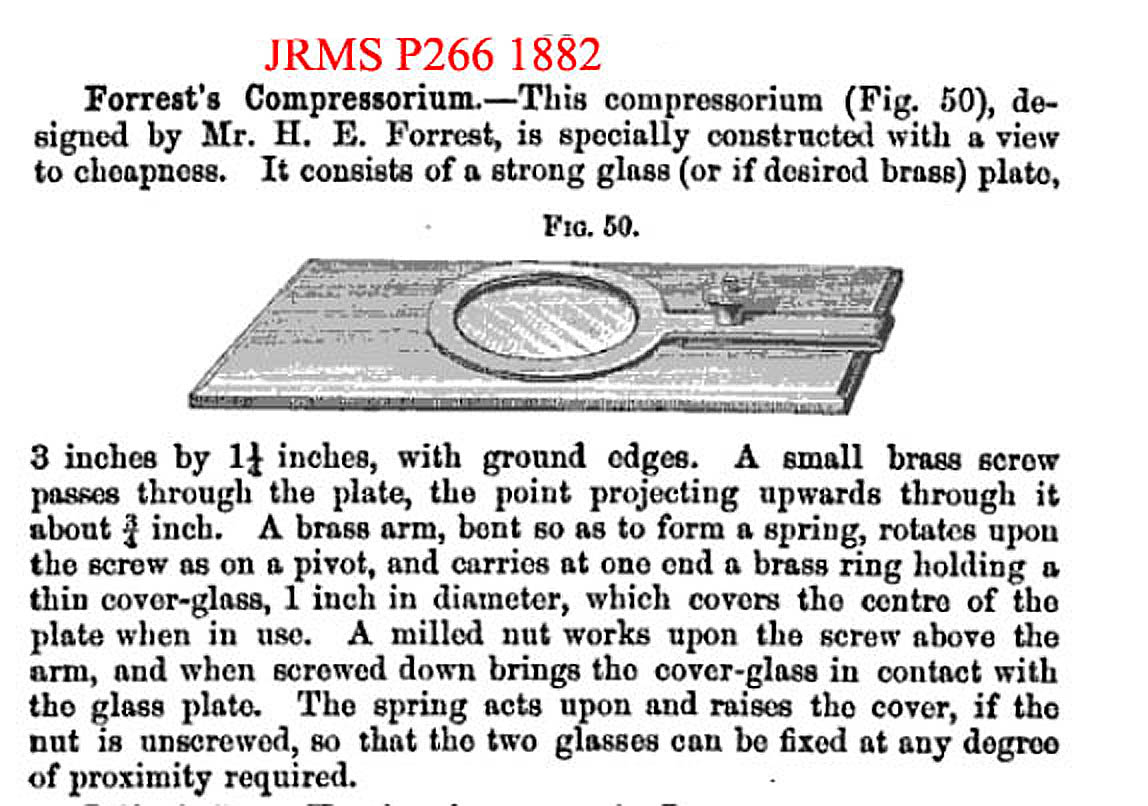

The Forest compressorium at first glance appears the same as the Wenham, but actually is the reverse, as tightening the knob moves the top plate down. In this case, the amount of pressure applied is not limited by the springiness of the top plate, since turning the knob applies the pressure and the springiness serves to keep the top plate off the subject when the knob is unscrewed.

The Forest compressorium at first glance appears the same as the Wenham, but actually is the reverse, as tightening the knob moves the top plate down. In this case, the amount of pressure applied is not limited by the springiness of the top plate, since turning the knob applies the pressure and the springiness serves to keep the top plate off the subject when the knob is unscrewed.

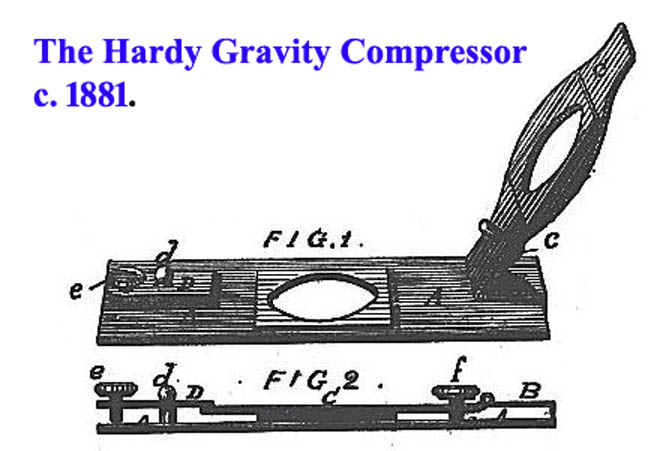

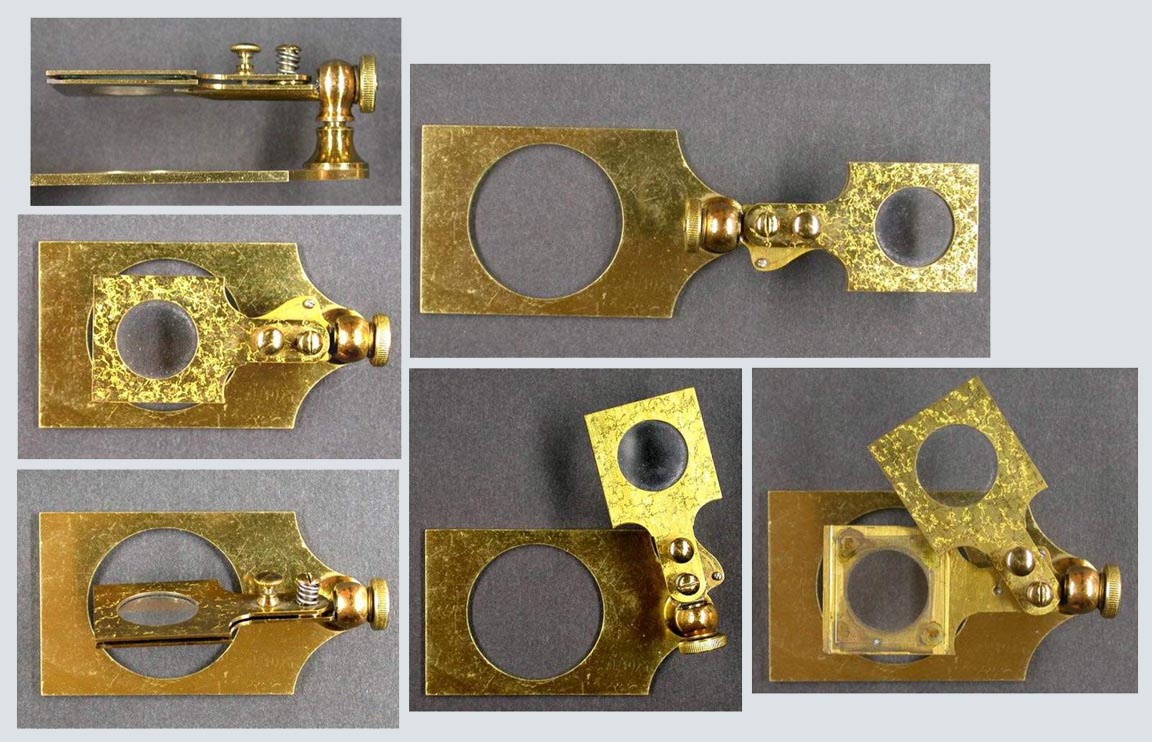

In the early 1880's, Phin and also Hardy both described types of gravity compressor which was hinged on one end. This design was later modified and improved by Martin. The

In the early 1880's, Phin and also Hardy both described types of gravity compressor which was hinged on one end. This design was later modified and improved by Martin. The  This compressor was noted in a

This compressor was noted in a  This compressorium, supplied with microscopes made by Walter Bulloch, is similar to the Wenham type on one side, but also incorporates features similar(but not identical), to the Hardy on the other- an added feature of a second knob on the opposite side of the specimen so as to apply pressure to the top plate from that side if needed or to increase the parallelism of the arrangement.

This compressorium, supplied with microscopes made by Walter Bulloch, is similar to the Wenham type on one side, but also incorporates features similar(but not identical), to the Hardy on the other- an added feature of a second knob on the opposite side of the specimen so as to apply pressure to the top plate from that side if needed or to increase the parallelism of the arrangement. This compressor, devised by Professor Y. Delage in 1886 is similar to a Schieck-type lever compressor, except that instead of using a lever, a screw acts on a wedge attached to the top plate holder. This type of compressor was made by Nachet. Like Schiek's original design, it has three pins standing up from its surface, allowing it to be reversed on the stage.

This compressor, devised by Professor Y. Delage in 1886 is similar to a Schieck-type lever compressor, except that instead of using a lever, a screw acts on a wedge attached to the top plate holder. This type of compressor was made by Nachet. Like Schiek's original design, it has three pins standing up from its surface, allowing it to be reversed on the stage.

This is a later version of the gravity compressor in its simplest form, as the compression is not adjustable and depends solely on the weight of the top plate. This design is not rare and examples exist in various collections including that of the Royal Microscopical Society. This example is signed 'REGD 244895.' Although this number seems to date to 1870 in the British Registration database, it does not seem to correspond to this device.

This is a later version of the gravity compressor in its simplest form, as the compression is not adjustable and depends solely on the weight of the top plate. This design is not rare and examples exist in various collections including that of the Royal Microscopical Society. This example is signed 'REGD 244895.' Although this number seems to date to 1870 in the British Registration database, it does not seem to correspond to this device.

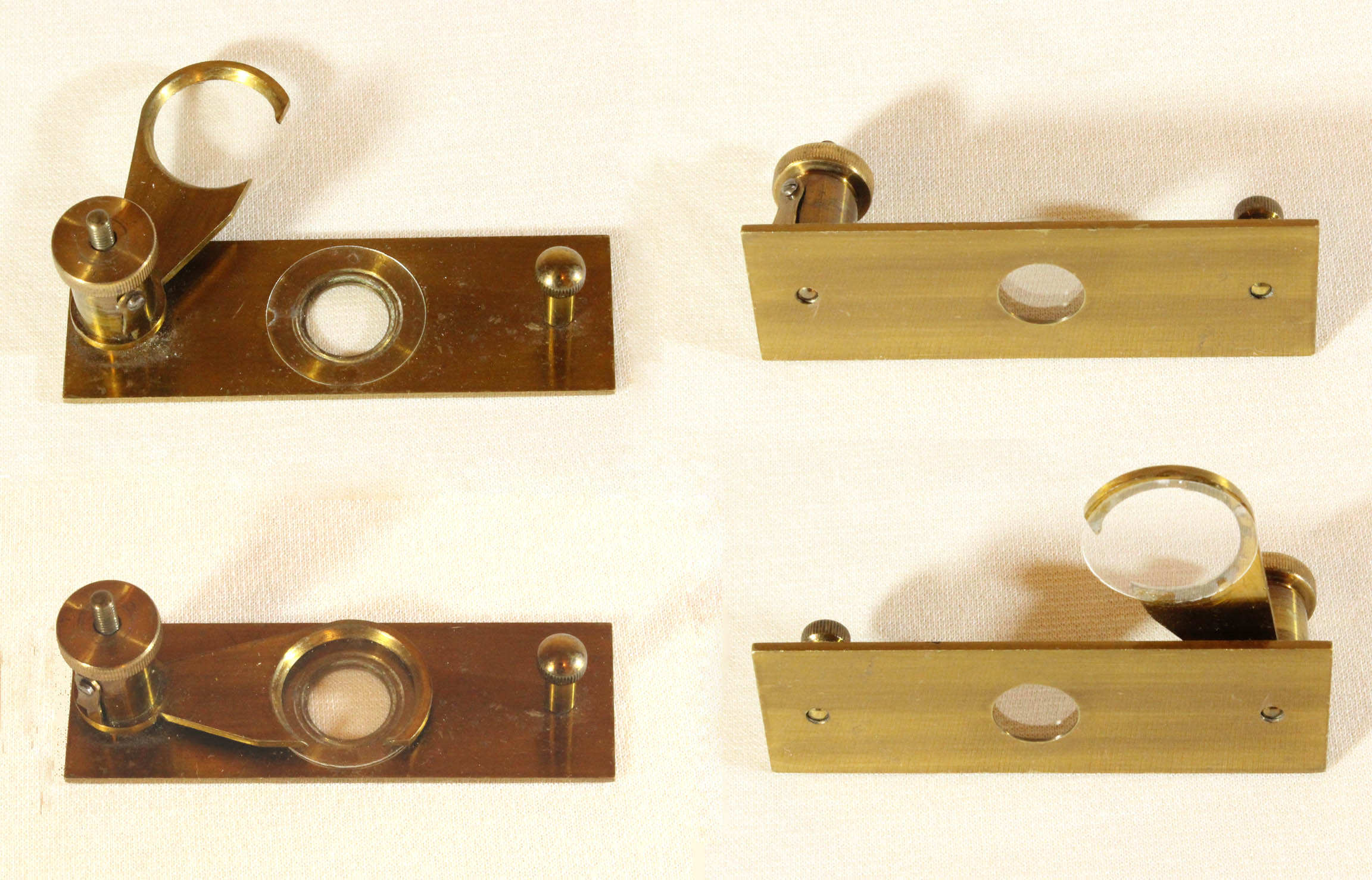

This compressor was invented by Charles Rousselet, FRMS 'about 1890' and was first noted in the JRMS in 1893. The general pattern of the top plate riding on a post 90 degrees from the bottom plate and the shape of the top compressor plate is quite similar to that of the Ross Swing-out Compressorium Stage of many years earlier. In 1903, Cross & Cole stated in Modern Microscopy that this compressor was the best type then obtainable. (Also, see

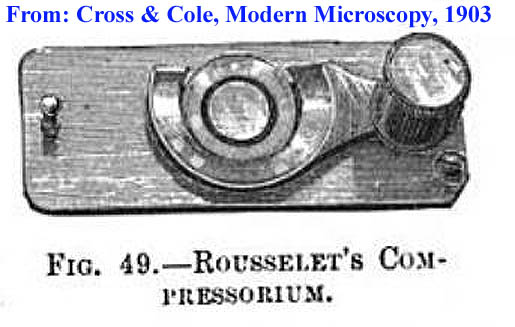

This compressor was invented by Charles Rousselet, FRMS 'about 1890' and was first noted in the JRMS in 1893. The general pattern of the top plate riding on a post 90 degrees from the bottom plate and the shape of the top compressor plate is quite similar to that of the Ross Swing-out Compressorium Stage of many years earlier. In 1903, Cross & Cole stated in Modern Microscopy that this compressor was the best type then obtainable. (Also, see  Another example of the type of reversible compressor invented in 1868 by Piper but this time attributed to W. Rowland. It has a much simpler construction and utilized coverslips cemented to the loops instead of fitting into recesses in the loops.

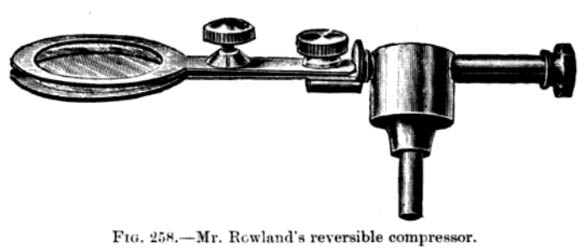

Another example of the type of reversible compressor invented in 1868 by Piper but this time attributed to W. Rowland. It has a much simpler construction and utilized coverslips cemented to the loops instead of fitting into recesses in the loops.  This is one of the modified Rouselet compressors, which makers like Watson called their

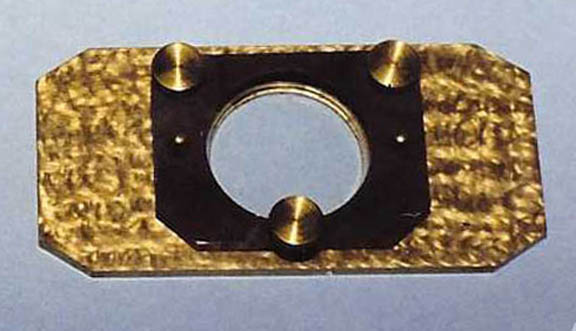

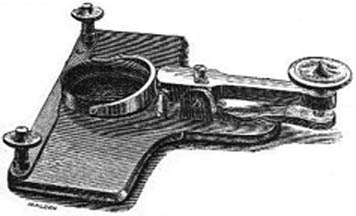

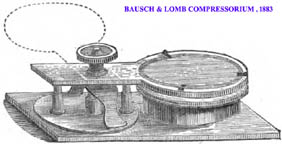

This is one of the modified Rouselet compressors, which makers like Watson called their  This type of compressor came into widespread use about 1870 when Virchow convinced the German authorities that microscopical meat inspection was critically important in prevention of trichinosis. They continued to be used well into the twentieth century and large numbers of specialized and relatively inexpensive low power microscopes known as 'Trichinascopes' were produced especially in Germany. This example, from a

This type of compressor came into widespread use about 1870 when Virchow convinced the German authorities that microscopical meat inspection was critically important in prevention of trichinosis. They continued to be used well into the twentieth century and large numbers of specialized and relatively inexpensive low power microscopes known as 'Trichinascopes' were produced especially in Germany. This example, from a

The Barnard compressor was first described by J.E. Barnard and F.V. Welch in the December 1928 issue of the Journal of the R.M.S. It was offered in the R. & J Beck Catalog of about 1930. It was designed for use with a high power objective and illuminator. Joseph Edwin Barnard(1870-1949), was a highly regarded amateur microscopist, who served three terms as president of the R.M.S. and wrote the book Practical Photomicrography which persisted through three editions. He was also known for his improvements in the ultraviolet microscope and his work with viruses.

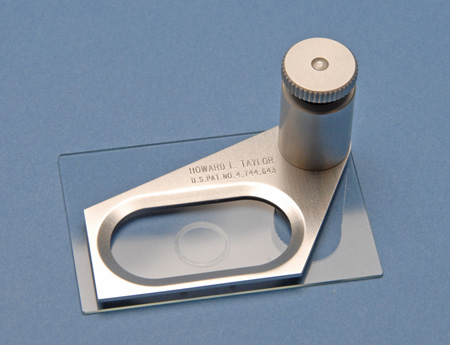

The Barnard compressor was first described by J.E. Barnard and F.V. Welch in the December 1928 issue of the Journal of the R.M.S. It was offered in the R. & J Beck Catalog of about 1930. It was designed for use with a high power objective and illuminator. Joseph Edwin Barnard(1870-1949), was a highly regarded amateur microscopist, who served three terms as president of the R.M.S. and wrote the book Practical Photomicrography which persisted through three editions. He was also known for his improvements in the ultraviolet microscope and his work with viruses.  The Taylor compressor is a modern version of the Rousselet. It features high quality construction and stainless alloy components. It has a very fine thread adjustment allowing perfect adjustments for things like rotifers-just enough to slow them down without crushing them to death. It also features an 'isolation mechanism' so that as the compressor is tightened, the top plate is not rotated in any way. This may be the best compressor ever made for this kind of work. It was not intended for high pressure compression like a trichinoscope compressor. It was patented on May 17, 1988 by Howard L. Taylor of Sarasota, Florida who studied rotifers. I do not believe these are in production any longer.

The Taylor compressor is a modern version of the Rousselet. It features high quality construction and stainless alloy components. It has a very fine thread adjustment allowing perfect adjustments for things like rotifers-just enough to slow them down without crushing them to death. It also features an 'isolation mechanism' so that as the compressor is tightened, the top plate is not rotated in any way. This may be the best compressor ever made for this kind of work. It was not intended for high pressure compression like a trichinoscope compressor. It was patented on May 17, 1988 by Howard L. Taylor of Sarasota, Florida who studied rotifers. I do not believe these are in production any longer.