MICROSCOPE-ANTIQUES.COM © 2013-21.

MACH-TYPE OF IMMERSION OIL BOTTLE:

c. 1897-1903

Maker: Carl Zeiss

In 1897, Gebhardt reported a new design of container for immersion oil designed by Dr L Mach of the Carl Zeiss company. Gebhardt pointed out the disadvantages of the types of oil containers available as of that time. He explained that as oil was removed, it adhered to the top causing the area to gum up which could lead to the lid becoming cemented to the top and very difficult to remove. He also explained that because of the relatively wide mouth of these bottles, air freely entered, and the oil tended to dry up and become more viscous. Lastly, he pointed out that using a glass rod, it was not easy to control how much oil was dispensed each time.

In 1897, Gebhardt reported a new design of container for immersion oil designed by Dr L Mach of the Carl Zeiss company. Gebhardt pointed out the disadvantages of the types of oil containers available as of that time. He explained that as oil was removed, it adhered to the top causing the area to gum up which could lead to the lid becoming cemented to the top and very difficult to remove. He also explained that because of the relatively wide mouth of these bottles, air freely entered, and the oil tended to dry up and become more viscous. Lastly, he pointed out that using a glass rod, it was not easy to control how much oil was dispensed each time.

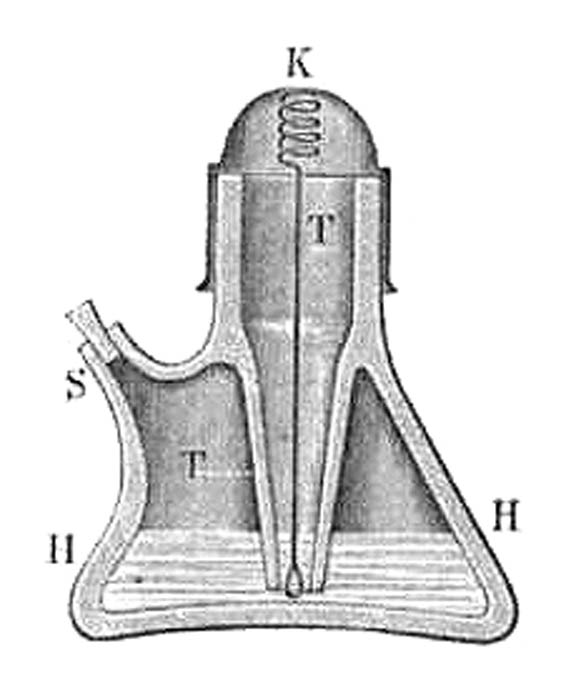

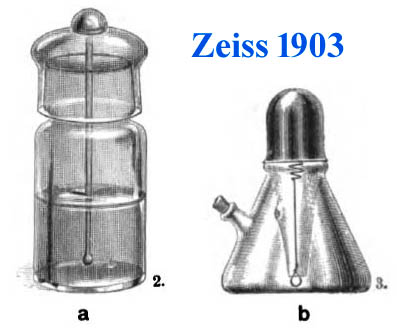

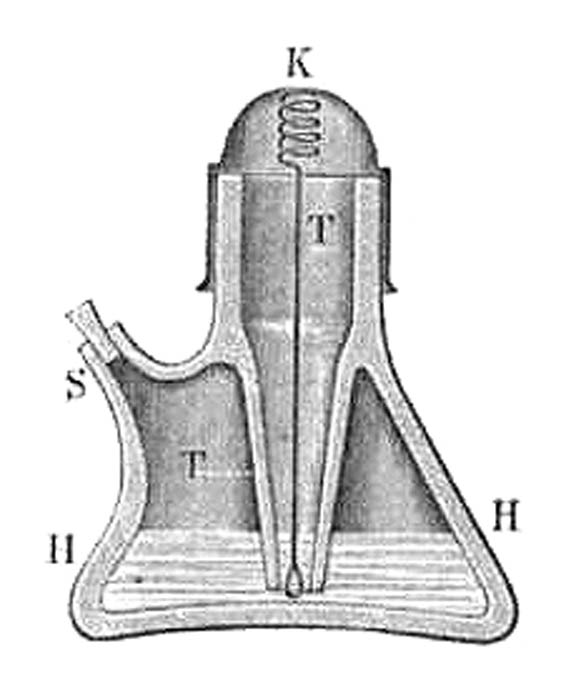

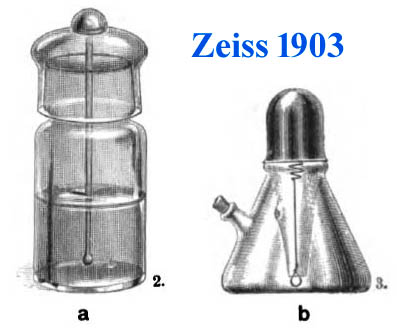

He explained how most of these problems were avoided with this new drip bottle. First, he pointed out that, the main bottle H, being shaped like an Ehrlenmeyer flask, was less likely to be tipped over. The inner funnel chamber was blown together with the outer main part, H. The inner chamber had a narrow opening almost reaching the bottom of the main vessel. The thin metal cap K, sits loosely on the neck of this funnel piece, and because it is so thin and has a thin inner shoulder, it makes little contact with the vessel and is therefore unlikely to be stuck to it firmly by any wayward oil. The wire, which descends from the cap downward, ends in a loop, reaching just below the end of the funnel piece, T. To get the bottle ready for use, oil is poured in through the funnel piece, whereby the side tube S, which is normally closed with a small cork stopper, must be opened to allow displacement of air. When being transported, the cap with the eyelet wire is removed and the opening of funnel T is closed by an ordinary cork stopper.

Near the vertex, the wire is wound like a coil to give it better springiness. When the side tube S is closed, oil cannot easily escape apart from being removed drop by drop by using the wire eyelet. It was pointed out that the bottle should not be filled much past the point where the wire is immersed in oil. It was also pointed out that each time the eyelet is removed, it takes with it only a small amount of oil and that any excess is automatically wiped off by the wall of the narrow part of the funnel. Because the opening at the bottom of the funnel trap is very small, there is little exposure of the oil to the outside air and it does not dry out. Because of the vacuum seal, even if the bottle is tipped over, no major spill is likely. This form of bottle was sold from 1897 until at least 1903.

*Gebhardt, W. Flaschechen zur Aufbewahrung des Immersionsols. Zeitschrift für wissenchaftliche Mikroskopie und für Mickroskopiche Technik 1897, pp348-350.

In 1897, Gebhardt reported a new design of container for immersion oil designed by Dr L Mach of the Carl Zeiss company. Gebhardt pointed out the disadvantages of the types of oil containers available as of that time. He explained that as oil was removed, it adhered to the top causing the area to gum up which could lead to the lid becoming cemented to the top and very difficult to remove. He also explained that because of the relatively wide mouth of these bottles, air freely entered, and the oil tended to dry up and become more viscous. Lastly, he pointed out that using a glass rod, it was not easy to control how much oil was dispensed each time.

In 1897, Gebhardt reported a new design of container for immersion oil designed by Dr L Mach of the Carl Zeiss company. Gebhardt pointed out the disadvantages of the types of oil containers available as of that time. He explained that as oil was removed, it adhered to the top causing the area to gum up which could lead to the lid becoming cemented to the top and very difficult to remove. He also explained that because of the relatively wide mouth of these bottles, air freely entered, and the oil tended to dry up and become more viscous. Lastly, he pointed out that using a glass rod, it was not easy to control how much oil was dispensed each time.