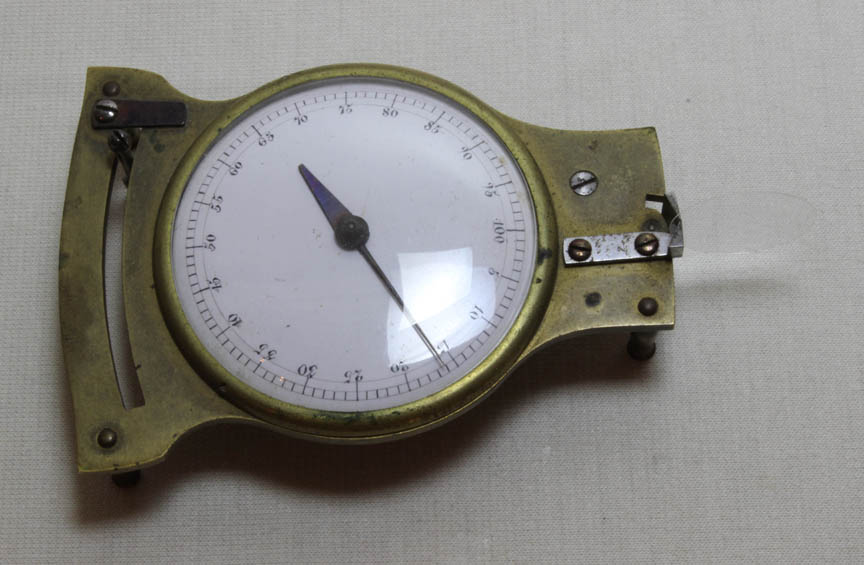

DESCRIPTION:

This instrument is made of brass, porcelain, and steel with three small brass support legs. As the steel arm is moved via a knob protruding through the front, the measuring jaws separate. The steel arm is then relaxed with the coverslip placed in the jaws, and the spring action brings it back to hold the coverslip between the jaws (middle image). The thickness of the coverslip can be read directly, in thousandths of an inch. The device makes use of a fussee chain attached from the steel handle to the interior gearing, best seen in the last image showing the underside of the device.

HISTORY OF THIS INSTRUMENT

As achromatic and aplanatic high power objectives became a practical reality in the middle of the nineteenth century, it became obvious that the introduction of a coverslip required changes in the distance between the front and back elements of the objectives. Not only did coverslips introduce new aberrations, but virtually no two coverslips had exactly the same thickness, so each required a different degree of adjustment. This was accompished via the correction collar which eventually was calibrated so that the approximate correction could be dialed in, provided the thickness of the coverslip was known. The coverslip micrometer was used to determine that thickness. The thickness of the coverslip can be read directly(in thousandths of an inch) from the dial which is made of porcelain. Many different types of coverslip micrometer were made by the various companies, including Bausch & Lomb, Zeiss, Beck, etc. The example shown here was likely made in France in the last third of the nineteenth century.