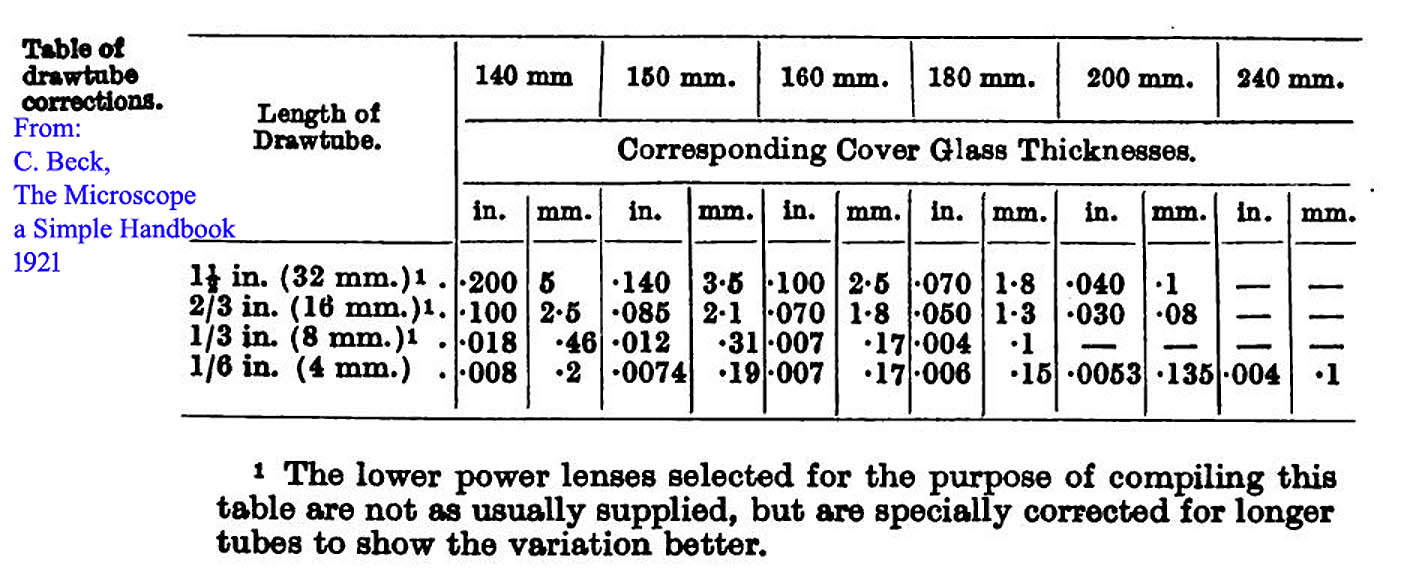

| INTRODUCTION | HISTORY OF COVERSLIP MICROMETERS AND TYPICAL EXAMPLES |

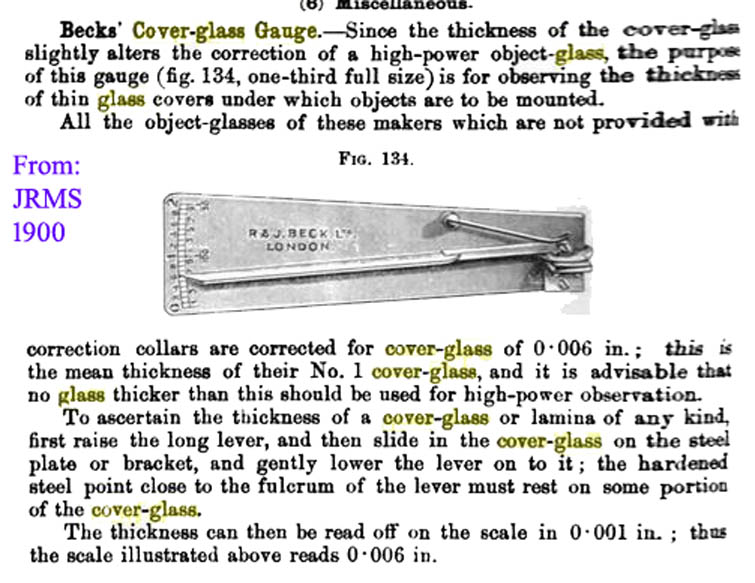

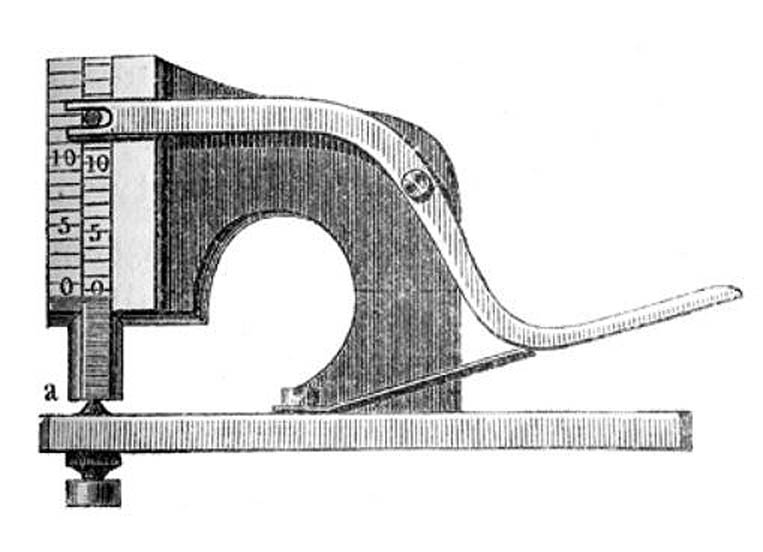

Probably the earliest form was known as the 'Lever of Contact' model and it was first made by Ross, as in the example shown to the left. It was described in 1853 in the Quarterly Journal of Microscopical Science p 142 and again in the 1856 first edition of Carpenter's The Microscope and its Revelations. Early versions were engraved with Ross's name using the 'long s' for the first s as Roſs but later is was spelled Ross. This device continued to be made and sold by Ross even in the 1870's as it was offered in his 1875 catalog. An almost identical instrument was brought out again in 1900 by R. & J. Beck as their 'new' cover-glass gauge (right).

Probably the earliest form was known as the 'Lever of Contact' model and it was first made by Ross, as in the example shown to the left. It was described in 1853 in the Quarterly Journal of Microscopical Science p 142 and again in the 1856 first edition of Carpenter's The Microscope and its Revelations. Early versions were engraved with Ross's name using the 'long s' for the first s as Roſs but later is was spelled Ross. This device continued to be made and sold by Ross even in the 1870's as it was offered in his 1875 catalog. An almost identical instrument was brought out again in 1900 by R. & J. Beck as their 'new' cover-glass gauge (right). Another type of coverglass micrometer is that which uses an accurately calibrated screw. The square-faced coverslip micrometer seen here was sold by John Browning in England and In Germany by Leitz. The German example was sold with Leitz's Stativ Nr 1 microscope in the 1870's. It may be the earliest form of screw-micrometer type. The example shown here has the stamp of the Pyramid brand of metal suppliers. Another example with a German microscope did not have that stamp.

Another type of coverglass micrometer is that which uses an accurately calibrated screw. The square-faced coverslip micrometer seen here was sold by John Browning in England and In Germany by Leitz. The German example was sold with Leitz's Stativ Nr 1 microscope in the 1870's. It may be the earliest form of screw-micrometer type. The example shown here has the stamp of the Pyramid brand of metal suppliers. Another example with a German microscope did not have that stamp.

The most common form of screw micrometer type, are virtually identical to the familiar micrometer, used by machinests and others, still in use today, except that these were built in to a stand.

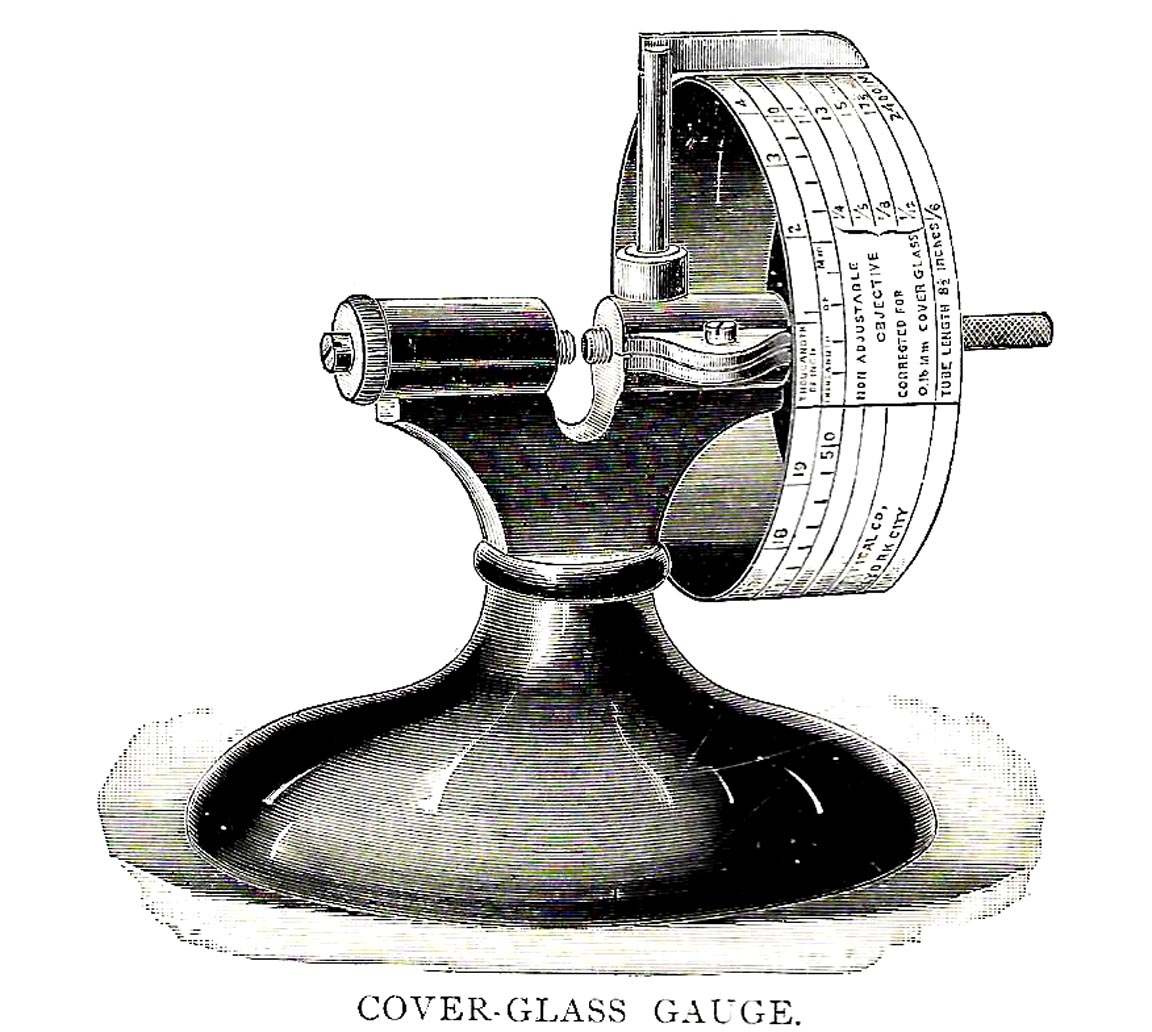

Examples were sold by Leitz, Seibert and also Zeiss in Germany(left), and by Bausch & Lomb in the U.S.A.(right). The example by B & L (right) had the unique feature of incorporating various scales including inches, millimeters, and even those for the tube length change for various objectives without correction collars. The German examples incorporated a ratcheting system to prevent overtightening (which could result in an inaccurate reading), just like the machinist's micrometers of today often do. This mechanism would also prevent breaking the glass. Another example of a screw-type Coverglass micrometer, by an unknown maker, which is made of lacquered brass is shown on this site. It also has a ratcheting system.

The most common form of screw micrometer type, are virtually identical to the familiar micrometer, used by machinests and others, still in use today, except that these were built in to a stand.

Examples were sold by Leitz, Seibert and also Zeiss in Germany(left), and by Bausch & Lomb in the U.S.A.(right). The example by B & L (right) had the unique feature of incorporating various scales including inches, millimeters, and even those for the tube length change for various objectives without correction collars. The German examples incorporated a ratcheting system to prevent overtightening (which could result in an inaccurate reading), just like the machinist's micrometers of today often do. This mechanism would also prevent breaking the glass. Another example of a screw-type Coverglass micrometer, by an unknown maker, which is made of lacquered brass is shown on this site. It also has a ratcheting system.

Soon after the production of screw micrometers for measuring coverslip thickness were marketed, dial micrometers for this purpose were offered. Although more expensive than the simple screw type, the measurement was faster and much easier to read using these. Both Zeiss(left) and Reichert sold virtually identical ones in Germany,with a nickel-silver or chrome finish with a wooden base, while in England(right) and France, many examples of slightly different design in Brass were sold unsigned. A French example, which makes use of a fusee chain, is also on this site.

Soon after the production of screw micrometers for measuring coverslip thickness were marketed, dial micrometers for this purpose were offered. Although more expensive than the simple screw type, the measurement was faster and much easier to read using these. Both Zeiss(left) and Reichert sold virtually identical ones in Germany,with a nickel-silver or chrome finish with a wooden base, while in England(right) and France, many examples of slightly different design in Brass were sold unsigned. A French example, which makes use of a fusee chain, is also on this site.

Another type, a lever micrometer, which in some ways used a design similar to that of the original Ross model, and made of lacquered brass, was sold by Wasserlein(left) in the early 20th century.

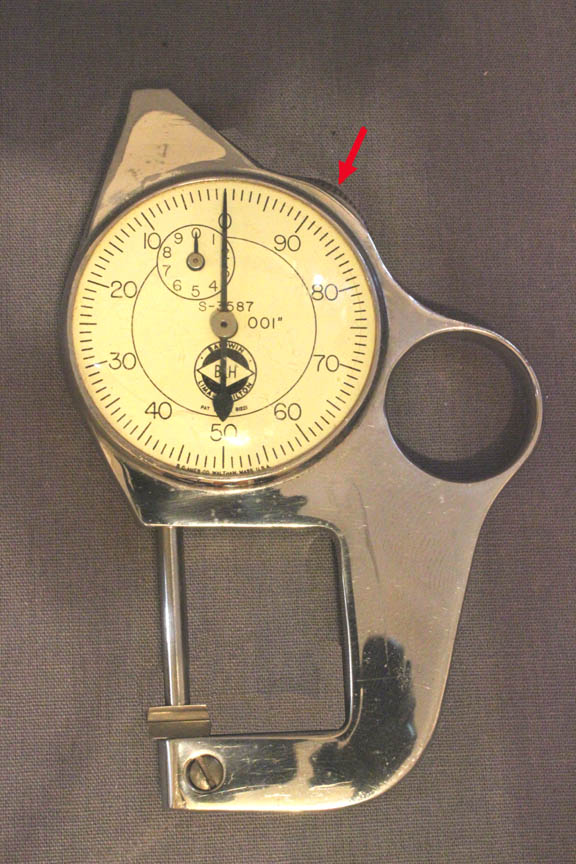

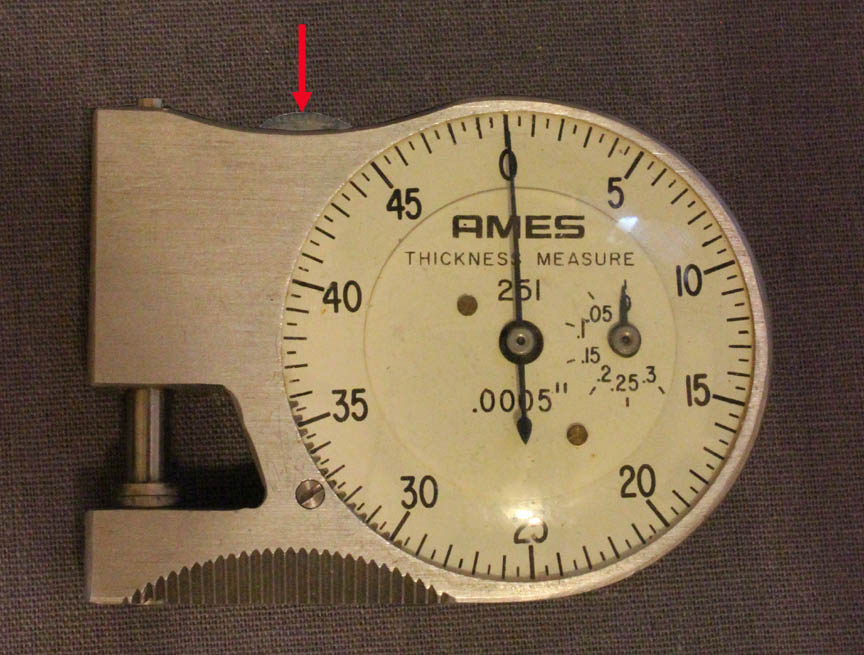

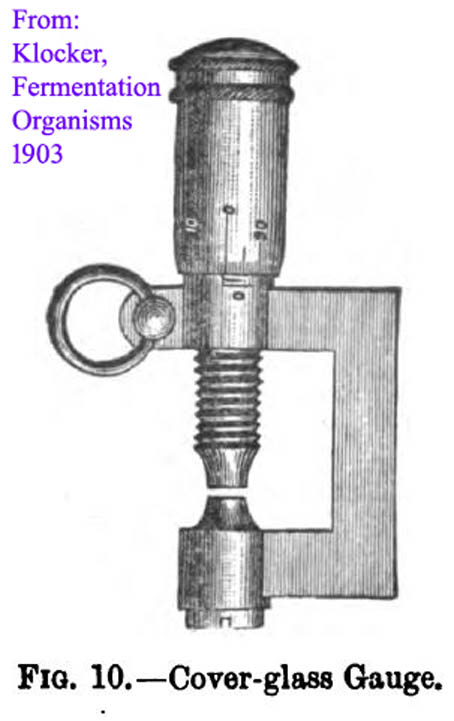

Another type, a lever micrometer, which in some ways used a design similar to that of the original Ross model, and made of lacquered brass, was sold by Wasserlein(left) in the early 20th century. An illustration from 1903(left) shows that machinist's micrometers were sometimes used specifically for measuring coverglass thickness. A variation of this shown to the right, uses a big dial to indicate fine differences in thickness. This unusual form seems to be undocumented. The following images show other thickness micrometers that can also be used to measure thickness of coverslips. Although not promoted specificially for this use, they all gave the same measurement on a coverslip as the Zeiss coverslip dial micrometer from a hundred years ago. The American Randall & Stickney thickness gauge is from the 4th quarter of the 19th century and is still accurate and easy to use today. The Ames company, founded in 1906, still produces the little 'Pocket Thickness Measure,' as well as other models today (2019). All of the gauges shown below were obtained in used condition, though still accurate, for very reasonable prices on Ebay. The red arrows indicate the knurled knobs to open the jaws.

An illustration from 1903(left) shows that machinist's micrometers were sometimes used specifically for measuring coverglass thickness. A variation of this shown to the right, uses a big dial to indicate fine differences in thickness. This unusual form seems to be undocumented. The following images show other thickness micrometers that can also be used to measure thickness of coverslips. Although not promoted specificially for this use, they all gave the same measurement on a coverslip as the Zeiss coverslip dial micrometer from a hundred years ago. The American Randall & Stickney thickness gauge is from the 4th quarter of the 19th century and is still accurate and easy to use today. The Ames company, founded in 1906, still produces the little 'Pocket Thickness Measure,' as well as other models today (2019). All of the gauges shown below were obtained in used condition, though still accurate, for very reasonable prices on Ebay. The red arrows indicate the knurled knobs to open the jaws.